There are some differences between the modeled autopilot and the one I have experienced IRL. In fact it is rather rare to get on a C172 that actually has an AP installed, I consider myself lucky.

One key diff was that IRL you can pre-set desired altitude AND VS before you actually engage the AP, which means you take off, you establish your desired VS and you engage AP for a smooth continuation of your vertical path. I haven’t managed to do that in the sim

In the sim

(1) When you turn the AP on, it does NOT capture your VS.

It goes to the last set VS. (so zero 1st time you turn it on, and next time you turn it on, whatever it was last set for)

(2) The ALT Arm does NOTHING (the re is no code there to do anything), and there is some other code, to do a kind of ASOBO fudged Auto Arm.

I have Modded my KAP140 to capture VS, and that part now works great.

Activating the flight director and stabilizing its parameters before engaging the autopilot works for me.

Regarding the OPs question, motorized trims aren’t unheard of in a C172. One I used to rent had an electrical trim control, and I think the Autopilot also controlled it.

And a Seminole I fly also had an electrical trim switch but it’s U/S.

So, if the AP can turn the trim wheel, and keep the plane TRIMMED, there should never be any excessive forces on the Elevator or elevator trim Servo Motors … and the dislay showing that the plane needs trim should never light up, and is redundant ?

It’s not redundant.

Almost every automatic trim system, even in airliners, has an out of trim caution/warning in case of a malfunction.

Maybe if the trim is too far out initially, the A/P won’t engage until the user brings the trim setting to a better position?

On the 4 cherokees and the DA40 we have: yes!

OK, so that should only display if a malfunction … GOOD … like the malfunction that causes the plane to go crazy when you turn on a “toppled” AP .

I now Asobo is currently looking at the AP systems, and one area of concern is their not initializing correctly, with excessive accumulated Integral components in the PID …

That I can also confirm, in case of malfunction of any part of electric trim (the 161 electric trim is FUBAR) it will light up the warning

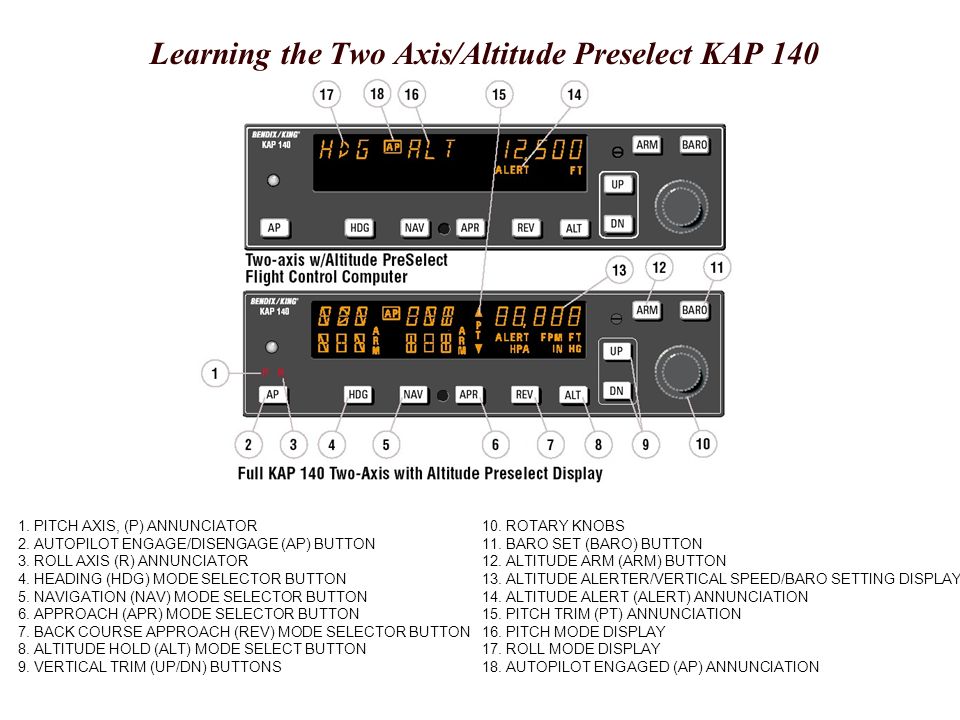

That is RW, because the ASOBO KAP140 does not even have those two warning Indicators to light up. they are not modeled in the left side of the Unit … they are lighted characters, not part of the main display

ref #1 & #3

#15 the Pitch trim error also does not seem to be functional on the Asobo KAP140, and as already stated, the ARM is totally Ignored.

IIRC Trim Fault ann light also comes on if the auto trim is operational for more than 10-15 seconds.

If the version of KAP 140 installed is single-axis, the (optional) elev trim only operates manual electric trim. In the two-axis autopilot, the (optional) elev trim can operate either automatically or manually. But regardless, the wiring and manual command always goes through the autopilot.

ie It After 10-15 seconds of running servo, it is still running the servo, because it has not achieved trim ??

Exactly - just found it on the manual, it is 15 seconds.

So Todays “update”’ was not the AP fix

Just maybe something to stop all the Carenado planes from their CTDs ?

@FlyinJPetrol, I use command “Elevator Trim Axis (0 to 100%)”. Works great. I love that command. Cheers.

You might find these two articles interesting:

Closed as by design.

“The NXIG1000 has 3 axis AP and so it makes sense that its like an airliners autopilot as its extremely expensive and not many GA C172 probably have it. Concerning the C172 classic it has pitch trim servo tabs and manual electric trim (KAP 140) meaning the trim wheel has to have a motor. Its a fully tricked out KAP140 which I doubt many have had the chance to experience irl leading to confusion.”