Turtle Beach Velocity One.

True, I forgot about the Turtle Beach Velocity although that has only just been released. It might have a trim wheel but theres a few things it doesn’t have which the Honeycomb does. Gear lever, flap lever, autopilot plus only has 4 throttle levers (Honeycomb has 6). It’s not as versatile in my opinion and there isn’t anything on the market which has what the Honeycomb has.

I would have to saw off the yoke then

According to an e-mail I received from Honeycomb last summer, it’s assembled in Hong Kong, but engineered in the USA. I believe the Parent Company is Aerosoft, and it’s European, I think. It’s does have all those levers, buttons, knobs, and the trim wheel is especially nice. It works for all and every plane either native to the SIM or aftermarket, even freeware ones. The price is a very fair amount for all the things it has. They need to ramp up quality. I like mine wish it was smaller in footprint.

So I received my second unit today and guess what. It’s not perfect either. Levers 3 & 4 are perfectly lined up (which is why I was returning the unit in the first place). However with the new unit also comes totally different issues that I never had before.

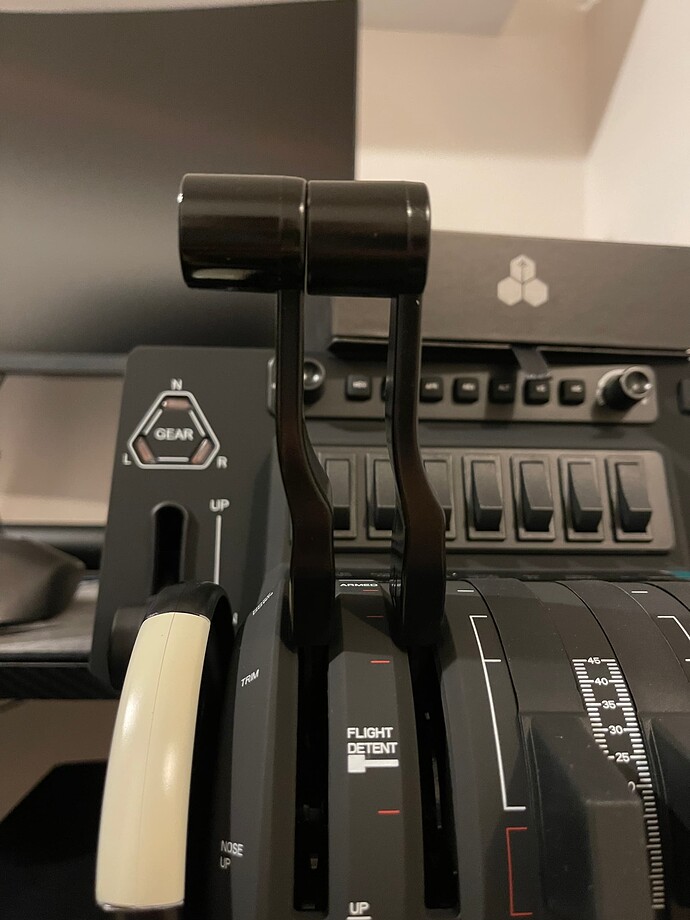

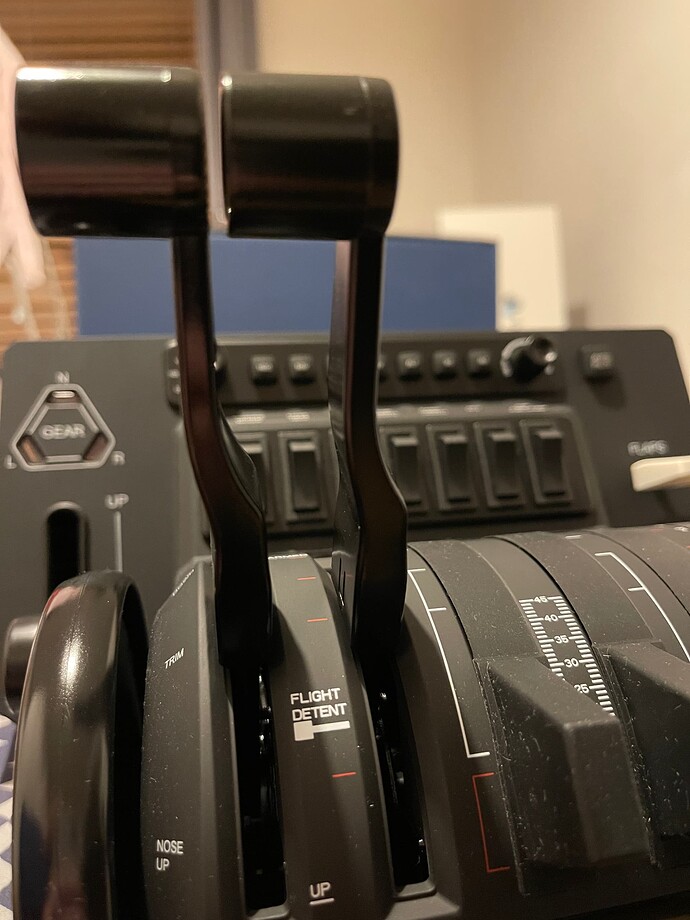

- Levers 1&2 are too close together, so much so that they touch and you can feel them touching.

This is how they should be with a small gap in between(as they are on my old unit)

Even the Honeycomb stock photo show a small gap. So this is how it should be

-

Some of the levers seem to have a dead zone in them. Where you can feel the lever move slightly before the lever actually moves if that makes sense.

-

The flap lever is wonky and not completely horizontal.

My old unit, as it should be

Seeing as this new unit has so many additional problems I think I will probably keep my old unit and learn to live with the slight misaligned 3&4 levers. At least I only have 1 issue on that unit as opposed to 3!

We shouldn’t have to live with quality problems like this. I don’t even know for sure that Honeycomb will accept my old unit for warranty repair if they deem it okay. I was even thinking about ordering another one but I doubt this will be perfect.

I had the same problem, but solved it by resetting the calibration setting in windows, and recalibrating in the MSFS.

I highly doubt that, sorry. The issues @TearlessFiend27 and I are facing are of mechanical nature and have absolutely nothing to do with software calibration.

Finally, my fifth (and “last chance”) unit has arrived. And finally, I have a keeper! The levers are perfectly aligned, the flaps lever fixed and leveled and, something I have not noticed on the four “faulty” ones before, the trim wheel is now properly fixed and turns much more “rich” and straight (not wobbly, loosely).

The device as it is now, is absolutely great. Honeycomb just seems to have a quality control issue…

Glad to hear your 5th unit is perfect, as it should be. If you don’t mind me asking where did you get your unit from? Are you UK based? I was thinking of ordering mine from the same place in the hope they are from the same production run.

Also did you get all your previous h it’s from the same place of different retailers?

First three units were from otto.de, the fourth one from Amazon and the last one from alternate.de.

I suspect, not having used a dial caliper on the levers, they are not molded to specs. Do the old levers work better on the New Unit? Wow, guess the first production fun was the best based on all the issues showing up here. I will possibly add the Virpil Throttle unit for those times I want to have just two engines controllable (although, the levers can be programed to run 4). It’s one of those decisions where it might be overkill in the peripheral department, since the HC works fine.

I’m wondering whether to keep my original one or try ordering another. I would have kept my 2nd unit but the flap lever being wonky just looked wrong. There was no way of correcting this as the actually lever is twisted and not the white plastic part. It’s a shame because all the levers on this one were perfectly aligned.

Did you not have any problems whatsoever with your 5th unit?

Finally zero issues.

When did Hong Kong leave China? ![]()

![]()

And more importantly, what country did they move to? ![]()

Hong Kong was independent from China for many years 1842 - 1997. They might be in the same country looking at a map but during this time it was run as a completely separate country under British colonial rule. It was handed back to China in 1997 but as a child growing up in the 80s I always think of Hong Kong as separate still. It must be my age!

I presume you’re not old enough to remember Hong Kong being a separate country? Technically they were never an “independent country” but we’re allowed to be run under separate laws and systems to China. It’s all very complicated and political hence the riots in Hong Kong in recent years.

I already returned mine since i had this issue and in my new throttle quadrant i have the exact same issue. Its probably just unlucky but in my case i wouldnt return it.

Does some of anyones honeycomb throttle levers tension are loser than others?

Yes, from right to left mine get’s looser. Because you tighten the tension on the right side, that side apperently get’s harder.

I know this thread is from December 2021, but I’m on my second Bravo and just had another issue. My first Bravo the reverse thrust stopped working on the #2 which they claimed was due to faulty wiring. They sent me an RMA and the throttle wasn’t working at all on the #1. They finally sent me a third one (This one) and this afternoon when pressing the flap lever up I heard a snap and the flap lever went limp in the housing. Looks like it still works, but is super sensitive. Oddly enough, they never requested to have the RMA back, so technically I have two units here in my house, both with problems. If they don’t answer my replies in a timely manner, it may be on me to open this thing up and see what broke.

Sorry for the late reply, but I have discovered and found a solution to this issue for anyone else having this issue and are not able to get an RMA.

If anyone is interested, I will provide detailed photos on how to do this or might even post a video on YouTube. Please let me know ~

The problem: Honeycomb uses ball spring plungers to create that “wall” that you must push through to get between the idle position of the axis and the downmost position of the axis. Here is what they look like: Ex Amazon.com

They screw into a socket that follows a rail and are held in place with a nut. What i discovered on mine is that each of these spring plungers were screwed in different amounts. What this means is in the idle position, while one axis may hit the “wall” at the tip of the spring plunger, those plungers that are screwed in more are hitting the wall closer to the sides of the actual ball on the spring plunger.

The difference between this is literally a fraction of a millimeter, but attach a post to it that is 3 inches long and stick a throttle attachment onto it, you get a noticeable difference of a couple millimeters like what you and I saw in our bravo flight controls.

I was able to fix this by removing the spring plungers from each axis and putting them back in, making sure each plunger had the same amount of rotations each into their socket. I then pushed the axises into the downmost position to secure them back with the nut. It took about 3 hours and lots of sweat to get this fixed correctly, but my throttles not finally line up with each other at idle within half a millimeter of each other.

Something like this could be so easily overlooked during assembly and I think that this is a product of inadequate instruction to some of the workers that may be assembling this product. I still think that at this price range it is unacceptable, but fixing it myself made me realize that the tolerances we are talking about are literal quarter or sixths of a rotation of the ball spring plungers. Honeycomb could have completely avoided this issue if they simply put a rubber grommet that would take force to push through because from studying this, the ball spring plungers literally serve no purpose other than this. Ultimately creating unnecessary points of failure both within the manufacturing process and with use and wear. Hopefully in future models, they choose a simpler and more reliable design for this.