I’ll do you one better if you want the TRUE Diamond experience… the second base unit I’m working on (project name “Aviator Pro”) is going to be a floor mounted base that will allow for stick use (Diamond, Extra 300, bush planes, etc) as well as pendular motion use (airliner, Citation, etc). It will utilize the same handle mounting functionality as the Aviator push/pull base, so all handles can be used interchangeably between the two bases. Obviously grips used on the floor mounted base such as the Diamond, Extra 300, etc would only work on that base, but I mean if you wanted to take the 172 style yoke handle currently developed for the Aviator push/pull base and put it on the Aviator Pro pendular base you could.

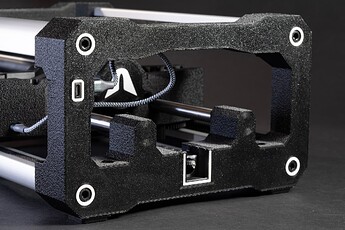

I’m about to post a new video on my YouTube channel showing the new strategy moving forward with these projects. Right now I produce fully finished/completed units, but the plan is to move towards DIY kit options. Since a lot of the parts on these units come from 3D printers, I want to offer the option to people to print their own parts (have full control over the color they want, filament type, etc), and then I will provide a kit containing all the other necessary components cut to size and ready to go (aluminum extrusion, bearings, hardware, PCBs, etc). The biggest thing this will allow for is the ability for me to lower the price. I’m a one man show doing this all in my basement, and so if I can remove the 3D printing/assembly part of it I can knock the price down which I think will make it a lot more desirable to more people. I really see this with the handles… if someone wants to take my handle design and print it themselves, the only thing they’ll need from me will be the buttons/HAT switches, shift register PCBs, and the cables. That’ll will drop the cost of a handle drastically, but then also allow the person to finish it however they want. Right now I have my printers set to add a texture on my handles as seen in the pictures, but if for example someone wants to paint their handle, or leather wrap it, or rubber dip/coat it… that would all be an option. They’ll have the STL file that would come with the handle kit, and then they can print and finish it however they want, then just install the buttons/switches/PCBs and cables from my kit so it all works flawlessly with the base units and they’re good to go.

Ultimately what I’m going for here is a semi-open source strategy for these yokes that will hopefully make them widely accessible to a lot of people (forgot to mention going to a kit option as opposed to shipping fully finished units means smaller shipping boxes which means I can do international shipping that won’t be ridiculously priced). I know there’s plenty of videos and stuff out there of people who have done their own yokes and provide details about parts and all that, but what I think has been missing is a fully fleshed out kit that has been procured and put together along with fully comprehensive build videos for someone to easily follow. Also having my custom PCBs means no one has to worry about arduino’s, learning custom coding, or any of that. It’s just simple assembly and plug-n-play.

Lastly, the best part of all of this… The FFB integration. FFB and writing software/code for all of that is way out of my league and the reason (along with cost) I simply went with bungees as the tension mechanism for these base units. However, I know FFB is at the top of a lot of people’s lists, and so that’s why I’m going to be incorporating the option for it into these base units. VPForce (TelemFFB) is an open source FFB solution created by a very smart simmer named Walmis. He originally created it for his FFB joystick named the “Rhino”, but it has widely been used by others to modify rudder pedals and other peripherals. I have been talking with Walmis and my plan is to incorporate his motors/boards into my base unit designs so that if someone wants they can easily convert them to FFB. They would simply just purchase the motors and boards from him and easily install into my base units, then utilizing his software get everything dialed in. My kit prices would stay the same regardless of whether you choose bungee or FFB since both options will be designed into the base units, so the only cost you would incur in upgrading to FFB would be the motors/boards from VPForce.

More details about this will be in the video I hope to post soon, but I saw your comment and wanted to let you know a solution for what you’re wanting is on the way! Things like yokes and throttles should be more modular like this and allow simmers the ability to customize to their heart’s content, and so that’s what I’m trying to develop here.