Wanted to share some experiences from a project that I recently completed.

It’s a button box that’s designed to cover the functions I use most frequently in flight, focusing on those things that can’t be done very well with my Stream Deck. So there aren’t that many actual buttons on this box; instead, I’ve got a lot of rotary encoders as well as switches whose position indicates the status of a given system.

The left-hand section vaguely mimics the knobs you would see on a G1000, but these functions can obviously also be used with other aircraft. The middle section has autopilot controls at the top and external light switches at the bottom. The right-hand side has controls for the gear, parking brake, and flaps.

There aren’t any displays – again, I figured I could do the same thing better with a Stream Deck – but I did want to have gear lights next to the gear switch.

In terms of components, I used Elma E37 encoders for the dual rotary knobs, CTS288V encoders for the single knobs (speed and heading), an Elma E33 encoder for the vertical speed wheel and an Alps Alpine RKJXT1F42001 combined rotary encoder and joystick for the range / pan knob. There are also various switches as well as a few LEDs. An Arduino Mega 2560 Rev 3 serves as the interface board, and it’s hooked up to MSFS using Mobiflight.

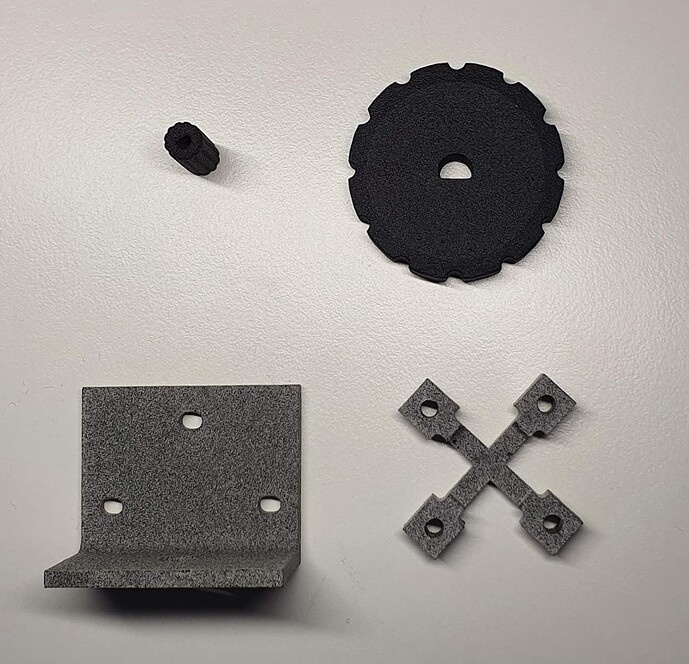

I designed 3D-printed components for the range / pan knob and vertical speed thumb wheel, as I was unable to find suitable existing components for these. I also 3D-printed brackets to attach the encoders for the range / pan knob and vertical speed wheel to the panel. As I don’t own a 3D printer, I had the parts printed commercially by FAMA3D, which offers 3D printing services using the Multi Jet Fusion (MJF) process. I was pretty satisfied with the surface finish and durability of the resulting parts:

Unlike the Fused Deposition Modeling process used in most 3D printers available for home use, MJF has the advantage that it can print parts of almost arbitrary geometry, including overhangs; this came in useful for the 3D parts I printed for the case, which I’ll talk about in a moment.

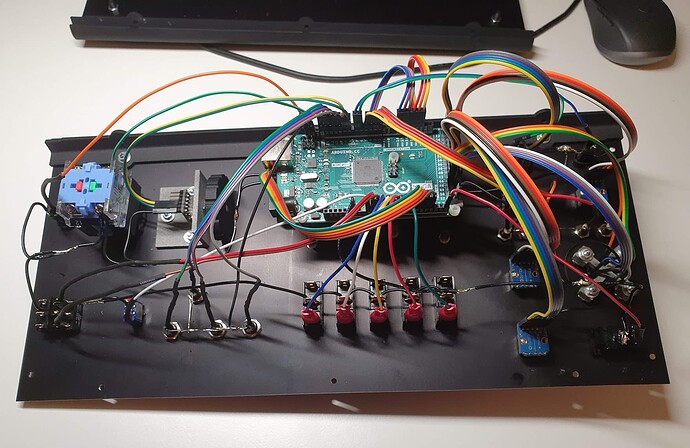

Here’s what the panel looks like on the rear:

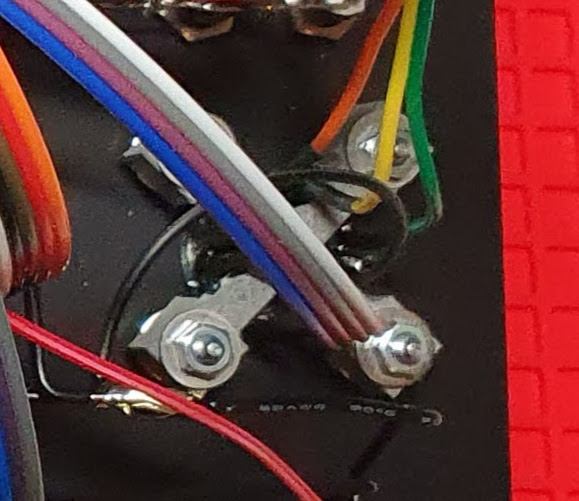

You can see the 3D-printed bracket for the vertical speed wheel near the top left and the bracket for the range / pan knob near the bottom right. (Please don’t look too closely at my soldering – I know I need a lot more practice. ![]() )

)

The front panel as well as the other aluminium panels that make up the case were manufactured by Schaeffer AG. They’re not cheap, but I can’t fault the quality and precision of the finished parts. The panels are connected using more 3D printed parts, as can be seen in the first photo.

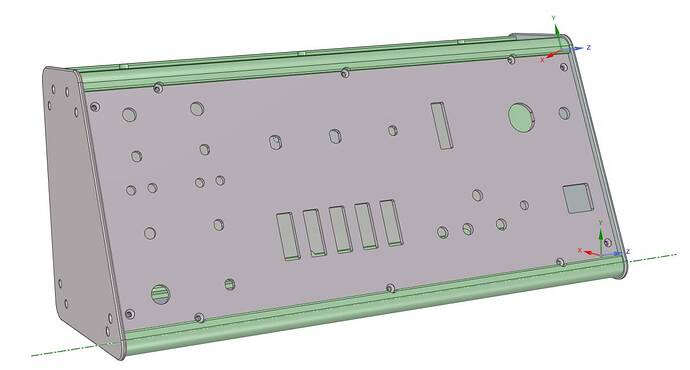

I designed the first 3D printed parts using Tinkercad, but it was too limited in its capabilities for the case parts. For these, I switched to DesignSpark Mechanical. This also came in useful for checking that all the parts would fit together as intended:

Lessons learned:

-

I didn’t give enough thought to how I would assemble the case. As it turned out, there were some screws in the middle of the case where it was extremely tricky to get a nut into the right place on the inside of the case.

-

The MJF process produces quality parts, but the finished parts will still have some dimensional tolerances, and this became particularly noticeable for the long case parts. I thought I had taken this into account sufficiently by making the screw holes slightly elongated, but I still ended up having to enlarge them using a file. The parts also ended up being slightly longer than the aluminium panels, so I had to file them down. Still better than having the parts end up being too short.

Happy to answer any questions!