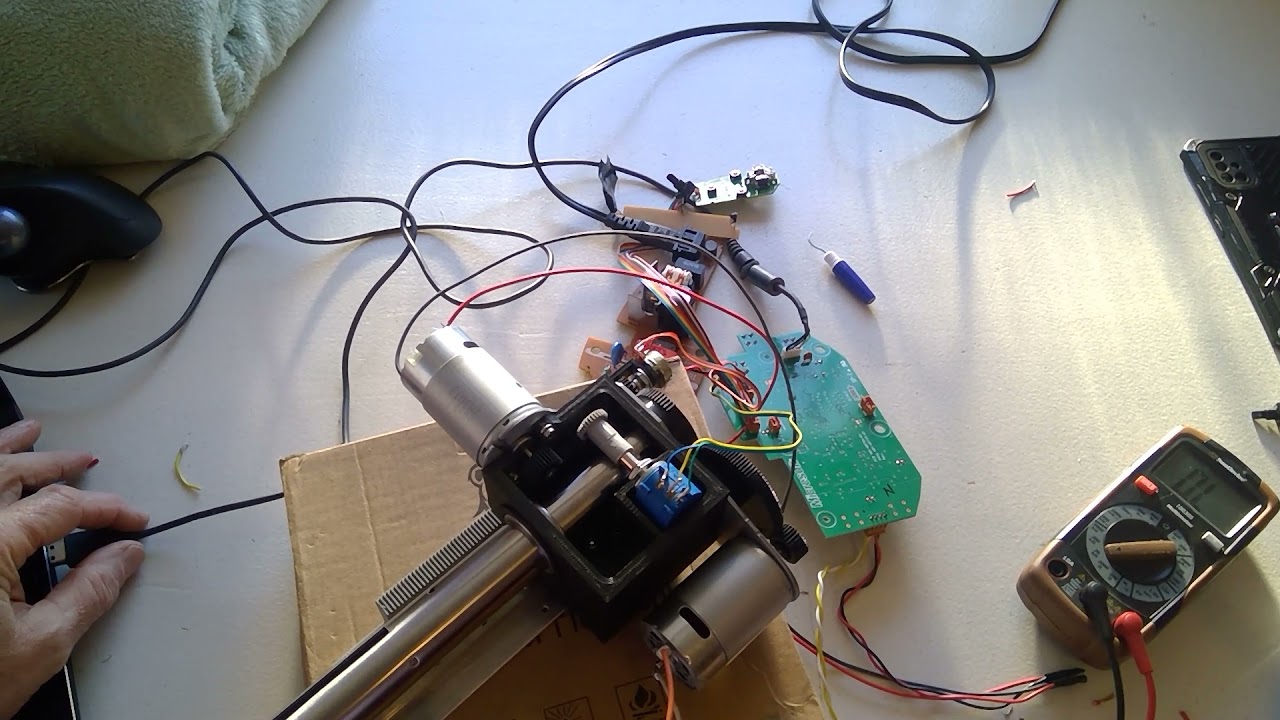

Yes the timing belt reduction is only 2:1 . I am going to try a different Pittman motor. I ordered it today off ebay. The one thing I wanted to try is to keep the moving mass as low as possible. The shaft you see on the roll axis is a new thing I am trying. It is called a linear ball spline. Its kind of a neat item. The pulley came with the assembly and cannot be altered. And the big timing gear is the biggest I could find. So the 2 to 1 ratio is it…

As I may of stated here before, until you fly the yoke on the simulator you are never sure what you really got. I am pretty happy with the pitch axis so its like 50% there .lol

The pittmas as-is is even too strong for me on the pitch axis, and with a fraction of the nominal power. I would say that, even considering the yoke width, if should be fine without reduction even there. If I could find a second one, I would for sure give it a try, unfortunately they are really rare in UK…

It works. I will be adding the resistors on the pitch axis, and maybe the roll as well. I’ll have to put a yoke on it first to see how strong the roll is first. I have it mounted to a box so it’s a little noisy, but the gears don’t feel grindy. Gotta go remove some of the internals from the Saitek yoke housing now.

Hooked it up to MSFS and everything seems to work. I like the way the yoke follows the autopilot. I will not be using the Saitek boards. I’ll just wire to the 12 switches on the MS board and print a blank with the Cessna logo for the display on the yoke.

I’ve come back home and tried a flight.

Really disappointing, actually. The yoke was bumping from one side to the other, but I don’t think it’s a fault of my code, I think that is actually what XPForce is telling my yoke to do. I start to think there is something wrong with it, wheels bumps are way too strong, taxing on ground pushes really hard the roll axis, and while flying it feels like someone is hitting my plane.

Also, the settings on XPForce seem to make no difference at all on the strength of the effects. While using test programs, the yoke is indeed receiving different settings for the forces.

Is anyone aware of other ways to interface a USB FFB device with MS2020? Just to understand if it’s a problem of XPForce or of my yoke…

I bet on the former case. You may end up where I am now - write a SimConnect client yourself. Unfortunately, this is like writing a simulator within a simulator. Although MSFS has got hundreds of variables that may be of concern, none of them are directly related to forces. The forces must be calculated from some of these variables. For example, there is a “gear compression” variable, that may be used for force calculations on the yoke while the plane is rolling on the ground.

The good thing about this solution is that the developer can decide on the volume of a particular variable in calculations.

![]()

But there is a second option. I’m re-installing XPlane 11 ![]()

Just to check…

I did finish up my ffb yoke and I am pretty happy with it. I got all the switches working using arduino micro pro boards. It is interfacing well with Fs2020.

Xpforce is a bit disappointing. I have to set the friction to zero, the spring to 10% and the pitch / roll to maximum.

With these settings it is useable.

The pitch and roll forces are very low. There is no turbulence felt in the yoke.

However the wheel shimmy and other useless forces on that menu are strong enough to pull the yoke out of your hand…

So ya. XPforce is lame software. If he would write a program that felt right when using the yoke I would pay the price…

Here is a pic of my yoke/cockpit. It is mounted on my 6dof motion platform and I fly in vr …

That looks really nice.

I found out that my issue with the yoke slamming from one side to the other was actually due to my code. I could not test multiple effects active at the same time (the test programs don’t allow to do it), while XPForce keeps active many of them. So, when this happened, the routine that calculates the torque was breaking up the transmission to the main board, so it was getting garbage instead of proper setting. I changed the interrupt priorities and optimised the effect function and now it works fine, no more slamming

As you say, XPForce isn’t great. But after flying a few times even with basic FFB like this, the time I went back to the yoke without feedback, it felt horrible.

Agree…

Have you tried AirForce Player 1.0.2 program?

I am a little cautious to change things right now…

I got the sim running the best it ever has.

The new OpenXR NIS upscaling software has made a huge difference in my setup.

I’m so bummed!!! Got everything mounted into the case and wired up. Still have to wire in the yoke handle controls and print the pass-through cover, but I was at least going to take it on a test drive. Plugged it in and the pitch pulled all the way back. I check it in the settings pane and the pitch axis wasn’t moving like there is an open in the pot circuit. Ohm tested the pot and harness. it all checks out good. deleted the drivers via USBDeview. plugged it back in. Still a nogo. I must have done something while mounting it. Static shock or something is all I can think. The only soldering I had to do to that board was the 24v power wires. Now I have to buy another MSffb2 stick. I was so going to fly this weekend. Did I mention how bummed I am?

Anyhow, everything fit in the housing nicely. The action feels good. I am going to lose the 10-turn pot because it creates entirely too much drag on the pitch axis. As it turns out, installing a slide pot will be a painless operation. I’ve already printed out the mounting bracket and ordered the pot. Here’s a pic.

Time to go bid on another stick…

If you ever have a problem with the yoke part, let me know. You can have my old one. I modified it with a external joystick card. So now it just has a 25 pin connector coming out the back. The only use for it would be a project like yours.

Can you still calibrate the joystick in windows?

Does the led light at all?

There’s no pitch motion detected in the calibration window. The roll axis is working just not the pitch. I may hook it to another pot tomorrow to test but I’m pretty confident it’s the board.

Ok. I have done some board level repairs on that circuit and have blown up my fair share. Usually the motor output area get blown pretty easy.** The pitch motor should run non stop if it is a pot problem.

I do not know if you are in the US or not but if you are check out shopgoodwill.com And search for “force feedback” you might find one for $10.

EDIT I reread your post and the pitch motor running continuous sounds like a pot problem. Do you have the original pots to try?

I’m going to try another pot today. I did test the assembly prior to getting it all mounted in the housing and it worked correctly. I was handling the board a lot while working on fitting it into place. It’s been very dry around here of late, and my cats were checking out the build. Pet the electron filled cat, touch the board, and zap; is probably what happened.

EDIT: Or I just wired it in completely wrong. What a Maroon… Got my wire colors mixed. Oops.

Nope, never heard of it. Let me search…

![]() so did you fix it? Was it just a wrong connection?

so did you fix it? Was it just a wrong connection?

Yes, I build collectives on the side using the same wire colors for the pots. I do bl, ye, gn. This one is bl, gn, ye. Must be that Covid brain fog they talk about…

I’m glad I got it sorted out, but I’m still going to swap the 10-turn pot for a slide pot. The movement without the 10-turn is virtually effortless whereas with the 10-turn, it’s like working against a viscous damper. I’ve already printed and installed the pot bracket. I also printed the jig to cut a slot in the mount for the pot actuator.

I still have to figure out the switch wiring. It seems as though MS did a matrix while Saitek did not. I have diodes if I need them. Or I may just mount one of the little Beetle boards I have and wire the switches to that.

Wow! Talk about high tech design work. Most of this is over my head but here’s a question.

I have three force feedback Logitech G29 racing wheels. Is the technology that drives these similar and can the electronics be repurposed for a FFB yoke? I know it would only be for one axis like roll but just curious if it similar. I’m not proposing tearing one apart since they are pricing that’s for sure.