There’s still no prop drag on TBM, is there a tool to tune the drag? Thanks.

I’m confused. They said even before this fix, there was prop drag, and I think they showed it in the wind tunnel feature of the aircraft editor. People keep saying “There’s no prop drag”. Have you measured the drag on the prop that you can make a statement that “Threre’s no prop drag”?

I don’t know, I’m confused and asking what measurement you made to make this statement as if it’s truth.

Try to fly an flaps up approach with the 350i and you will see that prop drag is still way too low.

The MSFS 350i offsets the lack of prop drag with a too high flap drag.

ROC with full flaps and gear down at 100kias is ~700ft/min.

IRL the 350i climbs in this config at 2400ft/min.

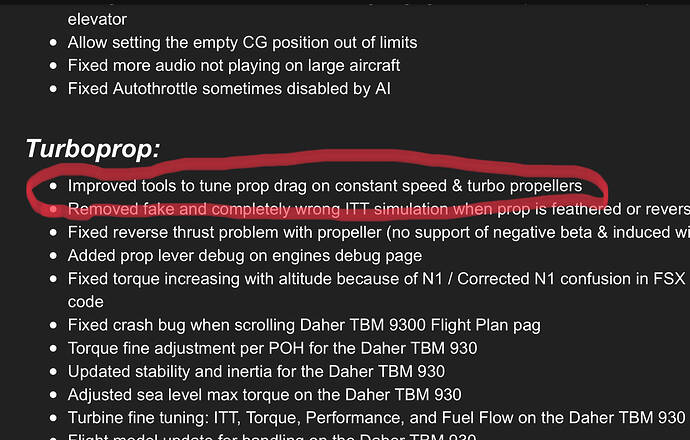

looks like that was an SDK change ‘improved tools to tune prop drag’ and not a change to the MSFS global flight modeling…

a concession to their 3rd party developer partners no doubt.

any change to a default Asobo plane will have to be made by Asobo / MSFS on their end.

As far as I can see in online sources, this prop drag is dependent on the angle of the propellor blades. You can’t tune that angle manually while flying, only its range. The angle is changing with throttle. As far as I know there are no controls. When your aircraft is in Community, you will find settings for “Beta Range” in the engines.cfg as beta_min, beta_cruise and beta_max in the [PROPELLOR] section. The range between beta_min and beta_cruise is used for reverse throttle (break) while landing,

https://www.flightliteracy.com/reverse-thrust-and-beta-range-operations/

Yes but I think the problem in this case is not to do with how the prop incidence is modeled but rather how the propeller interacts with the virtual atmosphere in MSFS. Drag coefficient is the problem not prop RPM or pitch settings

hi @FusionHorse151 smart remark.. I must say it’s late here and probably I’m going fly with the Blériot as usual after the red wine started.. I didn’t test it, I just found these beta range variables and online it says beta range affects propellor drag. If you really want to know if there is actual drag implemented in MSFS, I would suggest just try change these beta range settings on the SDK DA-62 aircraft, and see what the effect is. If the settings do not matter, there is no propellor drag. But if these settings do something, like if you fill in -10 or -20 (a minus value) for the minimal beta range it would slow down the aircraft while landing on low throttle. If you see that it works.

On turboprops there is no prop drag.

During windmilling (when propeller drag becomes significant) the propeller is always on the fine pitch stop. So you can take blade angle out of the equation.

Don’t know what “beta” means in MSFS. In real life the beta range is everything below flight idle so not relevant in the air regarding prop drag.

![]() so reverse thrust only works on jets ? Not on propellor aircraft ? or is the effect too small to notice..

so reverse thrust only works on jets ? Not on propellor aircraft ? or is the effect too small to notice..

Reverse thrust probably works on props as well in MSFS? Why shouldn’t it. I didn’t test it though, prop drag due to windmilling prop is definitely missing on turboprops, thats something I know for sure.

interesting though that it is specifically referenced in the MSFS document above to turboprops

IE: Improved tools to tune prop drag on constant speed and turbo propellers under the heading

“Turboprop”

The information I found said that the propellor blade angle goes into a certain (negative) range at low throttle.. and without changing the direction of the propellor rotation, it would start to put airflow toward the aircraft, lowering airspeed. I would be very interesting to know how that is done and if it helps for short landings. I’m definitely gonna test a negative beta_min setting tomorrow on DA-62.. see what happens.

that is how it works on the DeHavilland twin otter for example - and you might be able to fake it on the Diamond or any aircraft using the scalars in the flight.cfg file maybe…but that would not be accurate to any aircraft that hasn’t got the mechanical ability to reverse the props.

prop drag as I understand it occurs anytime the aircraft is travelling faster than the current RPM setting or rotation / blade angle of the prop can manage. In other words - if the prop isn’t pulling the airplane or maintaining its relative airspeed in cruise - then it should have a drag effect as the air is meeting resistance from the prop disc..until the airspeed is reduced to match the spinning propellers ability to match it.

only a ‘feathered’ prop would offer virtually no wind resistance or ‘drag’ to the relative airspeed - that’s WHY you feather a dead engine

The propeller blade angle only changes to a negative value in the reverse range, which means not in flight.

The direction of the prop rotation never changes. That’s not a boat!

IF you go below flight idle in flight, that’s what usually happens.

Farnborough Air Crash - YouTube

Yes correct but this won’t happen in the air as there is a low pitch stop which keeps the blades at a positive blade angle until on the ground. You obviously don’t want this to happen in the air at idle power.

Simply put, as soon as the propeller starts driving the engine instead of vice versa → the propeller is converting energy from the airflow into mechanical energy and thus creating drag. This isn’t really depending on any airspeed or RPM where the propeller can effectively “manage” the flow of air. At higher airspeed the propeller is windmilling faster when the engine power is cut, converting more energy from the airflow into mechanical energy, therefore creating more drag.

Except the propeller will never be able to “match it”, when no power is produced by the engine the propeller will keep windmilling down to almost zero speed. When slowing down the windmilling speed of the prop will reduce and so will the drag. With the engine cut the propeller will always be windmilling and create drag, no matter the airspeed. The term windmilling kind of says it all, its literally like a windmill in high versus low windspeed. Also this term “discing” does not make much sense, the propeller will never really create form drag like a flat plate.

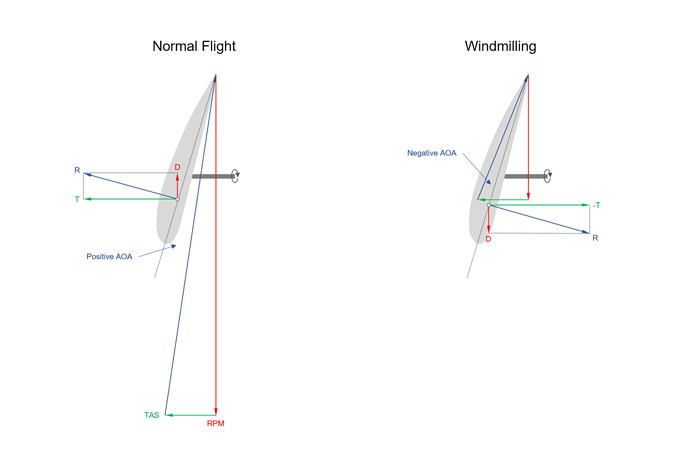

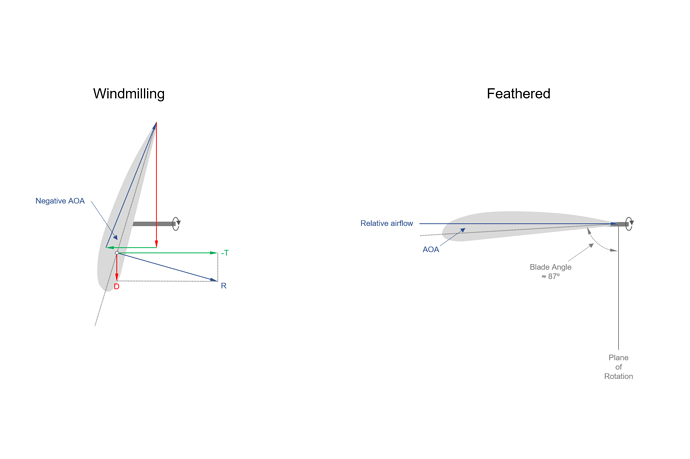

As can be seen in the pictures below, a propeller blade is basically a wing shape rotating in the vertical plane. It creates a force which can be split into a horizontal component (thrust) and a vertical component (drag), note that this is the drag slowing the propeller rotational speed, this is NOT the missing aerodynamic propeller drag we are all complaining about.

The angle of attack on the propeller is depending on a combination of airspeed (TAS) and rotational velocity of the propeller. In normal flight with the engine producing power those two will be in balance and create a positive angle of attack on the propeller. When the engine quits or power levers are moved to idle the rotational velocity of the propeller drops while the airspeed (at least initially) remains the same.

This will create a negative angle of attack on the propeller which basically flips the forces around. The horizontal component (thrust) is now opposing the aircraft movement and basically turns into aerodynamic drag (which is currently missing on turboprops in MSFS), the drag which before was opposing the propeller rotation now becomes the driving force and keeps the propeller and the engine spinning.

To reduce the aerodynamic drag during windmilling the prop needs to be feathered:

I have no way to measure the drag. I watched a few real world TBM pilots in YouTube in which they say the prop drag can act like speed brake. When you pull the throttle back the speed drops quickly like speed brakes are deployed. I don’t feel that braking effect with MSFS TBM.

My take on these SDK changes is that they’ve done it to assist 3rd party developers fine tune their aircraft.

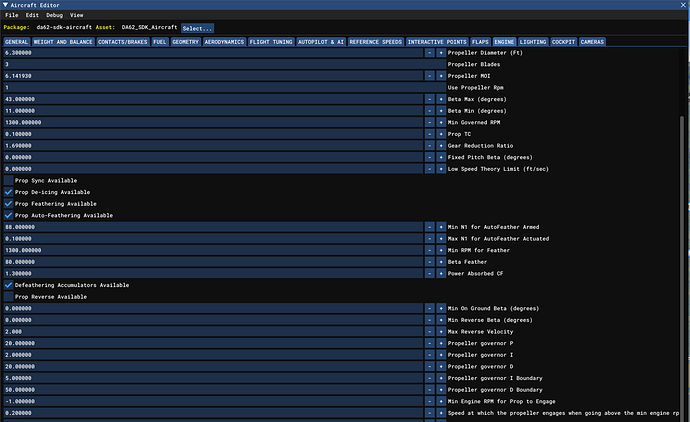

MSFS does have a propellor model. At least the inputs are there. See below. You get them when you load the aircraft project and Build it. Via Developer mode, you can download the DA-62 and install it. Then you can open project C:\MSFS_SDK\Samples\Aircraft\DA62. Load and Build.. Have patience, these actions take time.

Below the information I got from menu Tools / Aircraft Editor, tab Engines..

Aircraft uninitialized, the outputs (SDK menu Tools/Aircraft Editor, menu Debug Engines)

look like this,

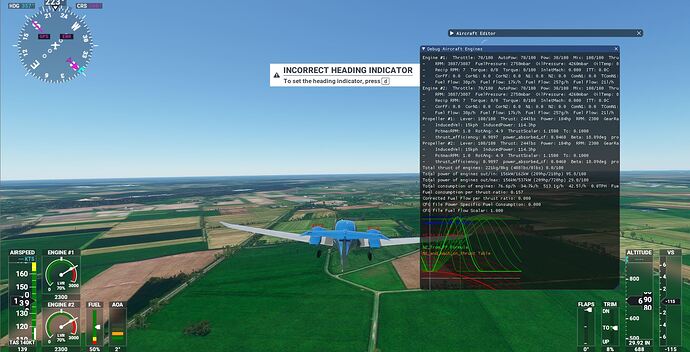

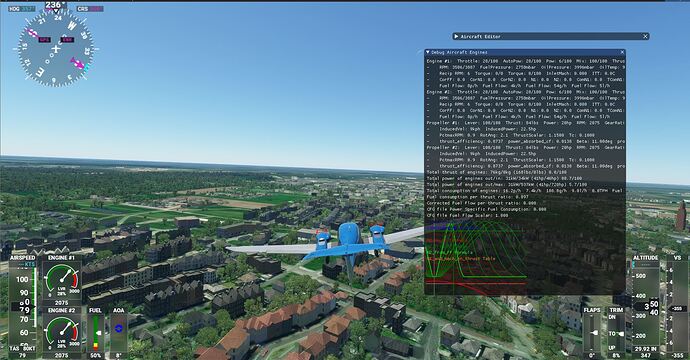

Some screenshots.. before takeoff it looks like this,

Output report at various throttle values..

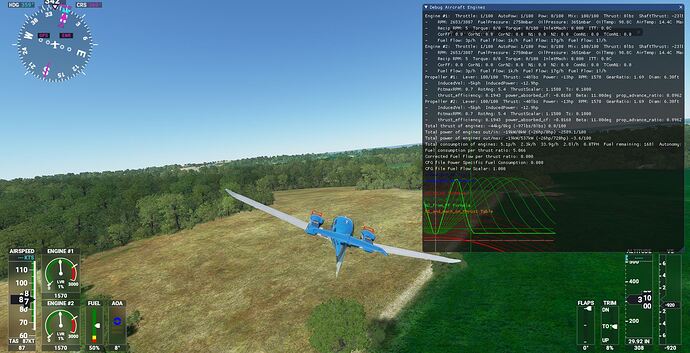

Below is the “windmilling mode” illustrated, taking back throttle from 16 to 1 causes the propellor speed to go to about 1600 Rpm, the forward speed causes the propellor to keep turning, but I don’t think I see airspeed going rapidly down at this stage.. Airspeed remains between 85 and 90 while the propellor keeps its “windmilling” speed, but I should note: despite the steep descent (VS=-925) the aircraft speed remains about the same. So you could say it is slowing down somewhat.. but I have the impression the effect is far less than using flaps.

(this is with the default settings, I have not changed things)