I was not aware of anything like that but I will look into it, thank you for the suggestion. I am pretty new to this so have some things to learn yet. I have been building and selling these for about 4 months now and has been taking up all my time!  Just sold a couple more in the past hour or two and almost out of stock (of built controllers, not parts to build more). So need to get back to work hehe. Takes about 1.5 hours to assemble/solder/test each controller once I have all the parts in front of me.

Just sold a couple more in the past hour or two and almost out of stock (of built controllers, not parts to build more). So need to get back to work hehe. Takes about 1.5 hours to assemble/solder/test each controller once I have all the parts in front of me.

There are plenty of 3D printed products about, the Spitfire stick and throttle assembly for example.

It is a good solution for small production runs where making the product out of metal is impractical and getting it mass produced in China is not an option.

I see bespoke 3D printed devices versus a moulded Chinese made product as equivalent to a hand made coffee mug versus a Walmart Chinese porcelain one. The Walmart version is cheaper and technically higher quality but I still prefer my coffee from the hand made one.

I’d say something like this: Plastic Electronic Project Box ABS Enclosure Instrument Case DIY Plastic Electronic Project Box 100mmx60mmx25mm|Wire Junction Boxes| - AliExpress

But bigger - they are out there if you search enough with the right dimensions. Then it’s all about drilling.

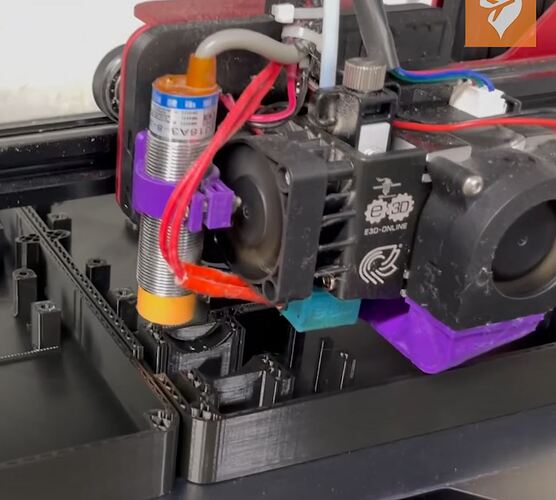

Ahh okay… issue with that is I have a lot of specific mounting points inside the case…like this here. This spot is the flap switch area, holds a few bearings and the switch etc.

Yep, 3D printing can make really nice custom boxes and enclosures with mounting bosses, holes, and even lettering and labels. Unfortunately nobody makes custom injection molded boxes that are appropriate unless you go with the plain Budd boxes and spend days laying out and cutting. At least with 3D printing you tell it to print and you can do other stuff. There are companies that will cut and letter faceplates of various thicknesses but that can get expensive for small runs. I’d bet 3D printing is the best solution for now if you are able to keep up with orders.

Yep I am happy with 3d printing them and I personally like the look of 3d printed stuff. I have 9 printers running 24/7 atm and that gives me enough parts to build up to 5 or 6 a day, which is all I could do anyway. I have been buying leo bodnar boards 100 at a time and the linear sliders/potentiometers 500-1000 at a time to help keep costs down, so I have a nice pile of inventory atm hehe.

The other bonus is you can easily make custom jobs.

If some wants a plain throttle with no prop and mixture, or maybe wants to add a landing gear lever or Piper Style rudder trim dial with a multiturn pot to the standard setup it is a lot easier to do with a 3D printed setup.

Cheers for that, yes it’s been fun creating it, I’m thinking of changing the Rudder trim from a 10 turn pot to a rotary encoder as MSFS doesn’t support an analogue axis for the Rudder or Aileron Trims.

Hope you do well with these, they look good.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.