My Logitech yoke has a dead zone from 12 to about 10 O’clock.

Response to the right is immediate, to the left not until I get to about 10 O’clock.

So far I tried to adjust through sensitivity setting without success.

Does anyone know how if dead zones are fixable? or

am I doing something wrong and whether MSFS can compensate?

Through the yoke out???

The Saitek yokes often have problems with the dead zone.

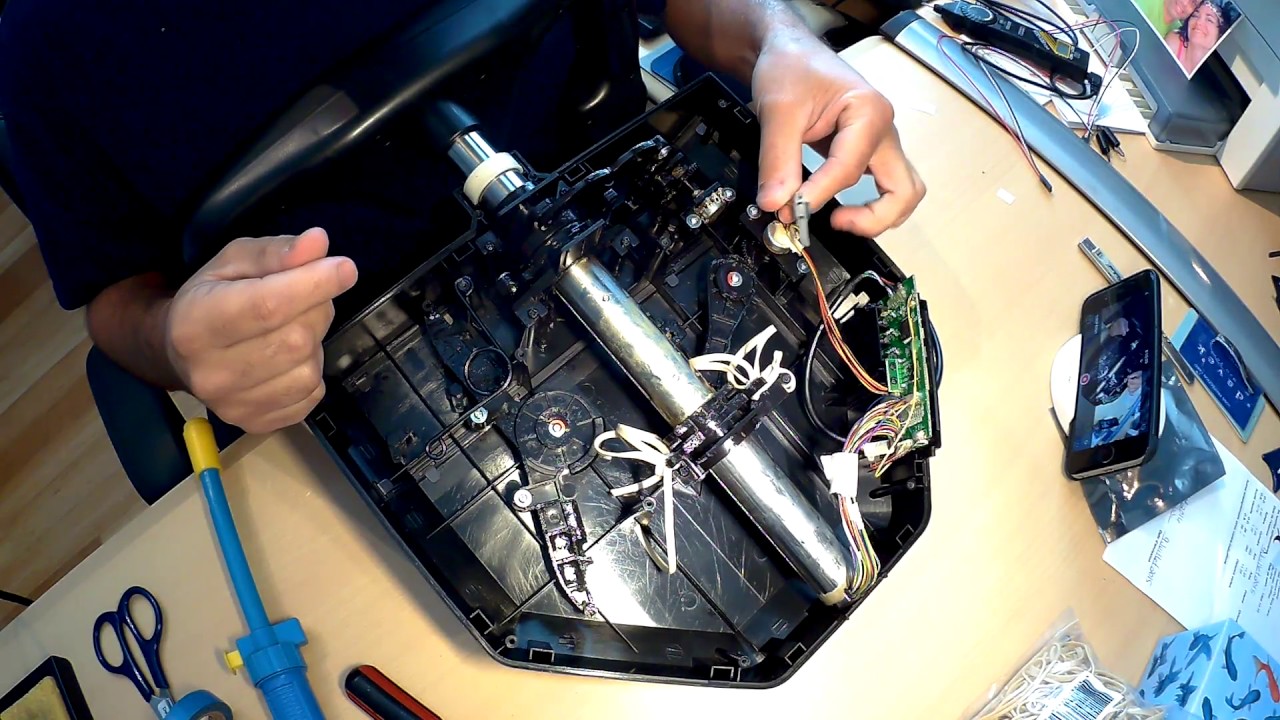

One solution is to solder in a new controller board.

Here’s a video that can guide you through and gives you a link where you can buy the controller board.

Recommendation to all owners of Saitek / Logitech yoke.

Thank you so much for providing the solution.

I followed the recommendations, purchased the board and cables.

I just finish the modifications which were easy to follow.

What a difference. not only eliminated the dead zones but it is so smooth and even in all axis. It is a pleasurer.

Real flying for 40 years, now gives me the pleasure to be much closer to the real thing.

For a small investment you get yourself a totally new yoke.

1 Like

Man, just got this Yoke two days ago, was having problems landing, and realized I have the exact same problem…to the right, no problem, to the left, dead zone, maybe 10 degrees . We’ll see if I want to go as far as soldering a new board, or just returning it. (sigh)

quick update on the matter, problem still persists in 2024 - bought a new logtech g yoke, lots of deadzone on all axis - it’s a “yoke” that they still sell this junk and won’t fix this issue. if you’re still deciding: don’t bother buying this, invest some more money and get something with reasonable quality

1 Like

Did you try using this tool to calibrate the yoke with.

It is one of the few that work well with Logitech.

https://heusinkveld.com/download-diview/

1 Like

I don’t think a calibration tool can fix physical/electrical dead zones. My long-donated Logi yoke had a large dead zone to the left.

Not if they are broken, but they often can correct large calibration issues.

I’ve not had a problem with mine.

My throttles were way off at mid point and the calibration corrected that.

Your results may vary!

1 Like

indeed, the calibration tool doesnt help at all in these cases, because i (and many others too) have a physical deadzone of 5-10 degress. which is utterly maddening when trying to do precision approach and flaring before touchdown.

logitech knows this and declares it a “feature”. seriously. it’s cheap bllsht is all what it is. they don’t even bother to replace the parts which are faulty - erm have this questionable feature - in later revisions as it seems. i terminally despise business conduct like this, they have gotten endless feedback about this and ignore it. and i can guarantee that this was the last ever logitech device i ever bought, and that whoever asks me about whether logitech gear is worth investing in will get a clear message.

Logitech is relatively inexpensive, but as they say: “buy cheap, buy twice”, or “buy once, cry once”.

1 Like

i still make these mistakes from time to time. sad but true.

1 Like

ok, so i too got the leo bodnar generic game controller and mapped in onto my y and x axis of the yoke. and i guess if logitech went ahead and used similar controllers in their product, it would cost them a tiny fraction of what i paid for the bodnar thing, which was around 50 euros, shipping and additional cables included. and it works like a charm. precise, no deadzone at all, that’s how it’s supposed to be. i threw out the ridiculous springs as well and replaced them with rubber bands.

huge shame on logitech. huge shout out to the community which offers actionable solutions, like this

or this

or this

or this

whatever floats your boat.

1 Like

A little bit of an update. After fixing the yoke itself, I now have a problem with the throttle quadrant.

Here’s the history so far. I’ll update it with more info as the story unfolds…

Yes, they are cheap, but the same as units costing 2-3x as much. The quadrant doesn’t have its own usb chip - it’s dependent on the circuitry on the circuit board.

Changing the sensor, etc. is going to change the ability of the chip to poll the quadrant. The quadrant will still work when plugged into an unmodified yoke. So now you have a spare quadrant that can only be used on unmodified yokes - but unmodified yokes already come with a quadrant.

So now you have to buy another quadrant with a usb connector instead of the din plug.

The circuitry has another problem in that when ambient temps are too high the yoke disconnects. Cured by putting a heat sink on the smaller of the two chips.

The latest production run doesn’t seem to have that problem, but will only know for sure this summer.

As for the dead zone problem, I haven’t run into it, but I don’t use drivers for the yoke, neither logitech’s nor the ones recommended by microsoft (disabled all driver updates from windows because windows update kept trying to overwrite my arc drivers for garbage out of date ones from my motherboard manufacturer).

Good luck.

The quadrant still works, and is connected to the original yoke board which I did not replace, I just added another one for the Y and X axis of the yoke. Buttons and everything else still works. But the quadrant is unusable due to jittering/erratic behavior which is most probably a result of dirt inside the sensors.

The. best way to tell is to plug it into another yoke. Just don’t blast it with compressed air (if it is dirt, just disassemble and vacuum it) and definitely don’t spray wd40 in it (it’s not a lubricant - the ‘wd’ stands for ‘water displacement’. That it ‘works’ for a while sometimes doesn’t mean it’s the smart thing to do).

The yoke and quad combo are cheap enough to have a second one handy for doing shared cockpit with two people on the same computer. Works like a charm.

Not necessarily. They’re potentiometers, if they’re replaced with one of the same type and values, should work the same. Generally the pots should have written their values and type (resistance and linear/logarithmic), but if not, they can be measured with a multimeter (provided first they’re desoldered, else you’re measuring the circuit).

They’re repleacable, I’ve replaced both pots and buttons in my old and beloved Saitek AV8R. Requires a bit of disassembly and tinkering but completely doable if you more or less manage basic electronics.

Proof of concept: Repairing a yoke while in flight is kinda possible.

WITH BLACK RUBBER BANDS!!!

Couldn’t stop laughing…

![Saitek Pro Flight Yoke System - Rubber band Mod Fix | Replace roll and pitch springs [Attempt 1]](https://img.youtube.com/vi/yZpIbT7gYqU/maxresdefault.jpg)