The layout generator worked quickly and easily. Almost as fast as just dragging and dropping a pre-made layout file. Thanks again for the hard work. You officially saved turbocharged aircraft for me and I am very grateful.

I will be working on tuning a version of the mod for the new Flysimware Cessna 414 tomorrow. In doing some preliminary research on the engine, I’ve found conflicting information. Does anyone have an operating manual or technical specifications for the RAM IV engine conversion which Flysimware is modeling?

An online POH for the C414a indicates that the original engines had the following specifications:

Continental TSIO-520-NB

Power: 310 HP per engine

Maximum Manifold Pressure: 38 inHg

Critical Altitude: 20,000 ft.

(source: C414A POH Pdf | Redcliffe Aero Club)

The Flysimware manual has different specifications:

Continental TSIOL-550A

Power: 345 HP per engine

Maximum Manifold Pressure: 41 inHg (red line on the manifold gauge in cockpit)

Critical Altitude: ???

(source: https://flysimware.com/website2019/wp-content/uploads/2022/03/Cessna-414AW-Manual.pdf)

Interestingly, the TSIOL-550 is a liquid-cooled engine (that’s what the “L” stands for in the model name). Is this a typo in the Flysimware manual? The RAM IV engine modification is air-cooled, and it is based on the TSIO-520-NB engine. (source: Performance-414A — RAM Aircraft, L.P.)

Another wrinkle is that at least one of the included liveries has a “RAM VII” decal on the winglet. The RAM VII conversion features a different turbocharger, as detailed here: Legendary RAM Engines for Cessna 414As — RAM Aircraft, L.P.

Since the real-world aircraft originally shipped with the TSIO-520-NB, and the Flysimware manual states that the aircraft is modeled on the RAM IV conversion, I think it’s safe to assume the following specs:

Maximum Manifold Pressure: 41 inHg

Critical Altitude: 20,000 ft.

If anyone has further information, I’d be interested to know whether the RAM IV conversion affects the critical altitude (is it higher than 20,000 ft?), and any details on the fuel metering system (i.e. does it compensate for decreasing manifold pressure above the critical altitude?)

Flysimwares Version has a tuned engine (RAM Aircraft Tuning - https://www.ramaircraft.com/). it has more power and higher max inHg.

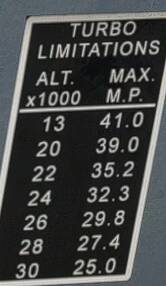

Critical Altitude seems to bee 13.000 for 41 InHG. You see a little Placard on the Mainpanel, with the max inHG per alt.

I have a version of the mod working for the C414, but there are a few things to iron out:

- The biggest issue is the clicking sound effect caused by moving the mixture lever. Since the mod continuously adjusts the sim mixture setting, the clicking sound is constant. Fixing this will require editing the sound configuration file. I need to dig around in the XML files to find a way to quiet the sound.

- The high-altitude performance also needs a tweak. Near 28,000 ft, the required mixture is very close to cut off with the current sim bug in turbocharger logic. The code I’m testing is still not fine-tuned enough for the range between 28,000 and 31,000 ft.

I will continue tweaking and testing.

I just released a version of the mod for the Flysimware C414. As always, you can download the latest files from my github page here:

Notable features: This mod assumes a fuel metering system that automatically adjusts for changes in manifold pressure. As such, the fuel/air mixture will remain constant even above the critical altitude, unlike the other versions of the mod for the turbo arrow, turbo bonanza, and Seneca. The POH for the Cessna 414A (source: C414A POH Pdf | Redcliffe Aero Club) indicates that the stock aircraft behaves this way.

In the real-world, the fuel/air mixture would still vary somewhat based on the efficiency of the intercooler at cooling the compressed air entering the engine. This would vary with airspeed, engine power, ambient temperature, etc. I spent a while trying to map out how to model those effects, but with no real-world data from a similar engine, my modeling attempts would be educated guesses – possibly significantly different than reality.

I’ve also re-tuned the controller constants to avoid overcorrection of the mixture axis at high altitudes. The result is a very slight lag in mixture adjustment at low altitudes (the lever will lag very slightly behind when you attempt to adjust mixture). In my testing, the lag appears to be a fraction of a second – hardly noticeable.

Note: The installation process for the Cessna 414 is more complicated than the other three planes. I’ve included instructions on muting the clicking sound effect when the mixture lever moves. Since the plane includes three distinct panel arrangements, the WASM file needs to be copied into three places. I’ve updated the instructions PDF to describe how to do this. Let me know if you have any questions.

The latest update from Flysimware enables automixture in the plane’s engines.cfg file. I’ve included an extra step in the instructions PDF to reverse this change.

What axis/control should my hardware be mapped to? I have assigned my hardware to the Mixture 1/2 axis in AAO (for the C414) and when I pull back the axis then the mixture randomly cuts out for a split second sometimes, even if I just slightly pull back above 21000 ft. And besides that EGT does not change anyway when, I was under the impression we have to adjust the mixture lever above critical altitude?

Just checking the obvious first: did you change the engines.cfg file to disable auto fuel mixture? If the mod is installed while auto-mixture is enabled, it can sometimes produce erratic behavior like you mentioned.

I don’t have any experience with AAO, but I set my mixture axes to mixture 1 and 2 in the MSFS control settings, so I would expect those assignments to work in AAO.

Ok, you have to map the AXIS_MIXTURE1_SET/AXIS_MIXTURE2_SET sim events to your hardware, as mapping to the Mixture 1/2 directly does not work.

Also fyi, in the panel.cfgs of the C414 GTN variants there was a change in the [VCockpit10] block you have to take into account and copy over when applying your mod.

I just updated the mod files to work with the new beta version 1.9.0.

I’ve updated the mixture mod for beta version 2.0.0 of the Flysimware 414AW Chancellor. The new version includes the mixture lever click sounds – tied to the hardware mixture axis, rather than the sim axis. So, when you move your hardware mixture lever, you should hear the classic Cessna mixture lever clicking noise.

I also updated the panel.cfg for the TDS GTNXi version.

The modded panel.cfg for the PMS50 GTN is currently not compatible with version 2.0.0. I am experimenting with the WTT patch from PMS50, which alters the panel.cfg from its original state.

As always, current mod files are located here:

Download the zip file by clicking the green “Code” button and selecting “Download ZIP.”

The mod is now up-to-date for beta version 2.1.0 of the Flysimware 414AW Chancellor. I’ve also updated the PMS50 panel.cfg. The mod uses the stock panel file. If you are using the WTT patch from PMS50, you will need to edit the panel.cfg inside the WTT patch folder, rather than the aircraft’s main folder.

For anyone with engine knowledge, I have a technical/calculation question. I’ve been looking at performance curves from the Continental TSIO-520-BE operating manual (not the exact engine model on the Cessna 414, but I’m hoping it’s close to a match, since it’s in the same model family). The manual is available here for anyone interested:

The manual includes EGT, CHT, and fuel flow curves for four specific power settings. I’m trying to calculate fuel/air ratio at different mixture settings from these plots, but the numbers I’m coming up with are not consistent. Here’s my procedure:

- Assume a perfect intercooler (induction air temperature is equal to ambient air temperature at mean sea level in a standard atmosphere)

- Calculate the density of air flowing into the cylinders using the density form of the ideal gas law (P = (density)RT).

- Calculate a mass flow rate of air to be used in combustion per hour. Since there are two piston cycles per combustion event in a normal gasoline engine, this should be:

mass flow rate = (density of air) * (engine displacement volume) * RPM * 0.5 combustion events per revolution * 60 mins/hr

- Take the ratio of fuel flow rate (from the TSIO-520 manual) to air mass flow rate (for a given power setting). This should be the fuel/air ratio.

When I follow this procedure for the four power setting graphs in the manual, I get varying fuel/air ratios for the peak EGT. Some of them are substantially less than the 0.068 stoichiometric optimum mixture, which is a nonsensical result. I suspect my calculation of the air mass flow rate into the engine is incorrect. Can anyone advise on where I’m going wrong? The perfect intercooler assumption might be a big part of the problem.

is the mod still compatible with sim update 10?

It should be. I haven’t been using the SU10 beta, but I’m not aware of any changes in SU10 that would cause a problem. If anyone else has run into an issue with the mixture mod in SU10, let me know.

I’ll take a crack,

13-5 States IAT of 115F at sea level on an ISA standard day.

Have you taken into consideration volumetric efficiency? Doing some quick and dirty calcs assuming a VE of 1 a 520ci engine should be using 376cfm @2500rpm and with an air density of 0.075lb/cuft I was getting sensible results vs the Chart on 13-8

Also can confirm the mod is still working well post SU10 with the Sen V so big thanks to @WxMarc ![]()