Apologies if this is a recurring inquiry, as I have made an effort to search and review the forum without finding any relevant posts. I am currently utilizing a Nextlevel Gt flight pack and additional equipment for Virtual Reality (VR) flying on my personal computer, specifically with Microsoft Flight Simulator (MSFS) and Digital Combat Simulator (DCS), along with occasional use for other games. Presently, I find myself confined to a rather cramped storage space under my staircase, as my pecking order is below the children and pets we now need to use this space for another use. As you can imagine, this arrangement is far from ideal. Residing in a limited-space, old-style cottage, I do possess a small portion of land accessible from my rear entrance it’s a wasted piece of land that I can’t do anything with and is secure by building walls. In my quest for a viable solution, I enlisted the services of a builder who offered a quotation of £2000 for a 10 x 8 lean-to roof, an expense surpassing my intended budget in these times when money is short for everyone. Essentially, I merely require a modest-sized shed that fulfills my requirements, neither excessively large nor excessively small. Additionally, I’d like to have aspirations of acquiring a Next Level v3 seat mover, or preferably always wanted to construct my own UH1 Huey helicopter collective and a do-it-yourself (DIY) 3D motion simulator. Unfortunately, space constraints have hindered my pursuit of these endeavors in the past. However, I came across a post’s on this platform detailing a method’s to build such setups for a few hundred dollars, akin to a 3-degree-of-freedom (3DOF) motion simulator platform, and plans for a helicopter collective. Regarding the electrical aspect, powering the shed is not a concern. Thank you for taking the time to read my post, and any advice or suggestions pertaining to the hardware size and anything else I should consider purchasing would be greatly appreciated. Thanks again for your time

Size is definitely hard to estimate without knowing what you want to have however, if we talk about motion platforms, they come in all shapes in sizes, especially the DIY ones.

Here is one of the “Cheap DIY motion seat mover” concepts that is well shown. He has a thread on the forums about it and various youtube videos showing it’s capability, price, and he also has cad files for his projects:

This setup is definitely one of the more popular options due to the cost, ease of construction. Because of weight restrictions (stall motor torque) Equipment is often limited to a chair, basic flight controls and VR (you could probably stretch in a monitor also on your seat mover but you will start hitting stall torque of motors, you can also keep the monitors outside of your motion seat however the immersion is more easily lost.) but as said before, is insanely cost effective, it’s also very size competitive, it’s not much larger than a general office chair with leg room to spare for rudder pedals. I would give a 120kg estimate for the amount a seat mover like that would be able to easily move, which if you’re light you could probably make it work but it would be a real challenge.

Now, if you want a better motion platform to put a replica sim rig on, non-commercial options like these are always good to look at for a reference to scale, as they provide many photos and images of the build process for DOF 3,4,5, and 6.

DIY Motion Simulator Projects (xsimulator.net)

There are all types of motion platform types there, you can also modify them within reason, you could make a forum post there with your specific needs and someone who definitely knows what they’re talking about would be able to critique/improve your design.

It also will heavily depend on the type of plane you make; I made a C172 simpit, the width dimensions for the panel were 1.05m, and with a chair I was looking at another 1m for length. The panel was about also another 1m from the floor. And a C172 is classed as a “small plane.” So ideally for a large range of motion you would need a pretty big range for linear actuators or motors which means they have to be further away from the platform to mount everything to. Fortunately, if your plans were VR, the saying often goes less is more, in terms of motion range there, it’s easier to fool the brain.

I guess if all else doesn’t meet your requirements for a baseline size, looking at a commercial option’s overall size would also be able to give you a decent scale.

Also make sure in the cost of your shed build that you have a way to route power and internet to your shed (often a wire from the house underground as my shed had done.)

Yes, you don’t need much room at all. See my videos from the post above, it’s really not that big. If you could fit a desk and an office chair - you can fit a compact motion platform design like mine. Remember to plan for ventilation - a powerful PC + all the motors and drivers + you in a small space - there will be a lot of heat to manage.

Thank you all for generously sharing your time and expertise. I have recently come across a website called sheds.co.uk, which currently has a 50% sale and boasts positive reviews on Trustpilot. Based on this information, I have decided to proceed with this option. Initially, I had reservations about placing the shed directly behind my house, but one advantage is that I will no longer receive complaints about disruptive noises, such as the bass shakers. I have devised a plan in my mind; however, as the saying goes, no plan survives initial contact. I will begin by measuring the dimensions of my existing confined space / punishment time out space. and anticipate extending it by a meter on each side, front, and back.

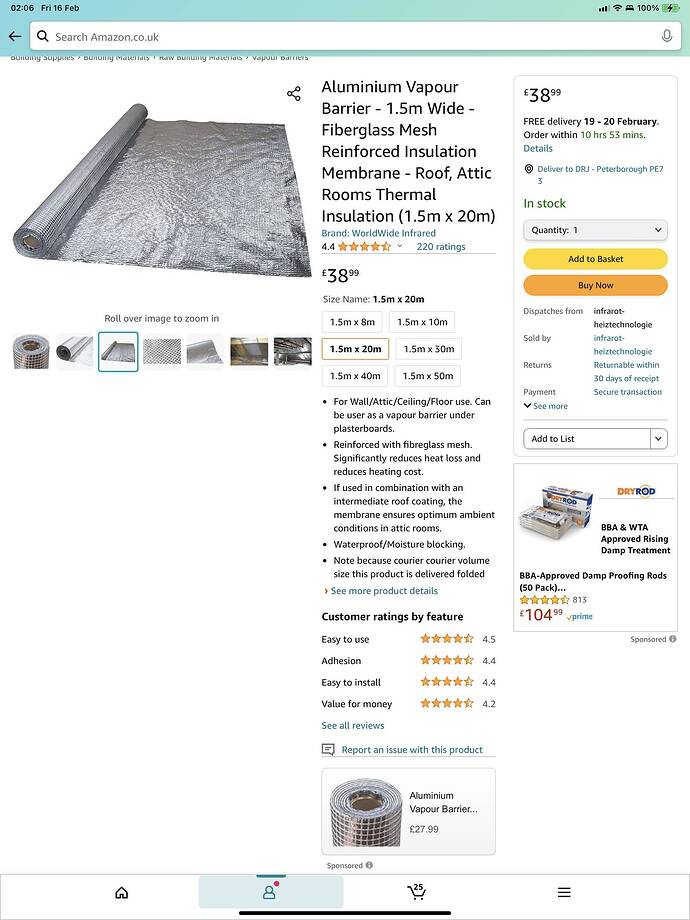

Research indicates that diesel RV heaters are commonly used to maintain a consistent temperature when the shed is not in use. My last concern revolves around adequately insulating the interior of the shed to accommodate all the necessary equipment, including computers, peripherals, switch boxes, and touch screens. I would be disappointed if I failed to properly prepare the space. So if I could kindly add to my existing post would you Kind ladies and gentlemen have any guidance on how I can insulate my sim pit from the extremities I was thinking about using something like a ecopro shed insulation kit that comes on a big foil roil, or would foam board be better but it seems far more expensive, just slightly concerned with the foil as to condensation.

As long as when building out the inside, you correctly insulate it keeping it warm shouldn’t be an issue, my tool shed contains computers running 3d printers, we get to about -3c in a bad winter, I haven’t had any issues with electronics from either the printers or the 3d printers, and I’ve just always heated it up with an oil radiator when I’m personally inside. Tech should easily be able to last hard conditions with ease.

In the case of my tool shed it was also placed on a concrete platform which made it much easier to fix to, and also provides as a solid floor base after painted.

Thankyou for your yuor response, did you vapour bariour then insulate wrap your shed, did you bother to plaster board or just leave the vapour barrior open, I’m not bothered how pritty it looks as I’m looking at getting a windowless security shed so utily is my main aim.

Forgot to mention I’ll be laying this on a solid rubber barrier sheets then wooden treated shed base, ill then barrier treat and thermal line the floor of the shed before laying carpet, may fit plaster board and paint them as it’s prob the cheapest part of the whole project.

Watched: the vid several times and capied the shopping list to my bear shopping list it’s awsome and what I’ve wanted for years to finish of my pit, only wish he could nip round and sort it for me.

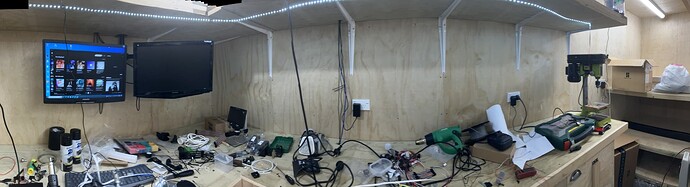

There was a plastic sheet that went between the tin and the framing which provides as a barrier for any holes (assuming that there hasn’t been a leak it has probably worked), tin shed, then a ply frame, insulation, and then lined with plywood 20mm thick. No windows either, Here’s some images below of what I have throughout the process. the interior had a wooden table mounted straight to the wall, but of course in your case it can be different. The shed size there is 2m x 5m which has worked out well for my purpose

Star.

Thankyou for taking the time to post those pics, that’s what I had in my head from a night of research on the ipad, going to fix this vapour barrior to the wood with spray glue or staples

Then probably try and leave a small air gap if possible then going to insulate with this -

Watched the screwfix videos on it and it’s meant to be equivalent to 55mm foam board insulation and it’s only 1.2mm thick.

So I just need to decide now what to clad my walls with as plywood cost a fortune, so may have to be plaster board then just give it a coat of emulsion.

I think I’m feeling a touch of shed envy! (That’s a real bloke thing).