A quick question to the RL pilots out there. What would you say is the preferred method of shutting down piston and turboprop engines?

I usually go by close throttle, cut fuel pumps, then slowly close mixture levers and then magnetos. I wonder however if there’s a specific sequence of events with regards to engine care and the technical logic behind that.

Thanks in advance.

Not an IRL pilot. It’s in the checklists for each plane. Generally, turn off all nav/radio/electrical equipment, throttle idle, idle the mixture until it cuts off, then deselect the fuel tanks and shut down alternators and remaining switches.

3 Likes

Each plane is different but for GA based on sim experience with the POHs and checklists.

Bring down the electronics / avionics and the. Engines.

Fuel mixture and flow off then magnetos off then alternator and battery.

Check out this page for checklists which can also be printed in a booklet format.

They are old and but off previous sims but for older aircraft the procedure would be the same.

1 Like

Thanks a lot for sharing. Good website!

2 Likes

Basically the reverse of startup, unless the checklists say otherwise.

Usually fuel pumps (after vacating you can usually turn those off already), avionics, mixture, when the propeller has stopped turn the magnetos off followed by fuel selector, then alternators, lights, battery switch. That is usually the procedure, at least you won’t damage anything this way. The mixture and magnetos never the other way around. Should you turn magnetos off first, there would be unburnt fuel mixture in the cylinders which could ignite when magnetos fire when someone hand turns the propeller.

A lot needs to go wrong for this to happen of course, first of all you would have forgotten to turn the magnetos off, have a broken magneto earthing cable causing it to remain online, or have someone not hand turning the propeller opposed to the normal direction of rotation. In any case that is the reason, its a good idea to take one more thing out of the fire triangle should any of the above occur.

Regarding the broken earthing cable on the magneto, magnetos are designed in such a way that they run when they aren’t “earthed”, this way, should an earthing cable break during flight, you won’t lose your magneto. You switch off the magneto by earthing it, with a broken earthing cable you will be unable to turn the magneto OFF and you would have no way of knowing. That is why so much precaution is taken to prevent the propeller from chopping someones head off.

This is exactly the reason why we do the magneto check before take-off. First of all we check the drop when selecting one magneto and ensure the engine doesn’t run rough, this could be a broken magneto or foul / broken spark plugs. On the other hand we also check if there is a RPM drop at all! No RPM drop at all could indicate the other magneto wasn’t running in the first place (you will find that out soon enough because when selecting the other magneto the engine would stall), or one of the magneto’s does not turn off (as explained above), either is a no go. In the latter case make sure nobody turns the prop by hand or gets into the prop area!

1 Like

A bit of topic but I noticed the Cessna 172 can be started in a way the real aircraft can’t be started and I believe it doesn’t start using the real world procedure but I’m not 100% sure about this.

The default C172 has an indirect injection engine, meaning that a fuel nozzle continuously sprays fuel behind the intake valve rather than the fuel being directly injected into the cylinder at the right moment. This means that the C172 cannot be started with the mixture full rich! In real life the engine would flood and fuel would poor out of the exhaust in liquid state.

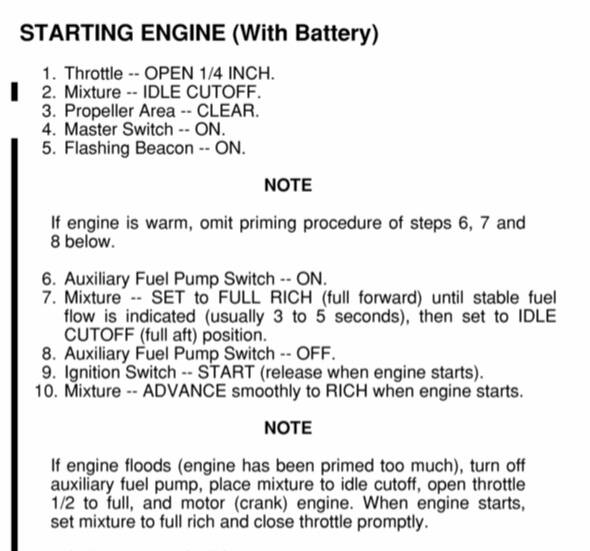

The usual start-up procedure is to open the throttle slightly, turn on the fuel pump, then open the mixture for x amount of seconds, or certain fuel flow on the fuel flow indicator (if installed) is reached. Then mixture idle cut-off, fuel pump off and that is the configuration the engine is started in (mixture cut-off). As soon as the engine fires up, smoothly advance the mixture to full rich.

I’m not 100% sure about the correct C172 start-up procedure but it must look like the above, that is the only way a indirect injection engine can be started without flooding the engine.

Edit: found the C172S start procedure:

Edit: the start-up procedure in MSFS does not make any sense. The C172 can be started with mixture full rich and pump running for minutes, in real life the engine would have been flooded completely. It could also be started with mixture idle cut-off, but you don’t need to prime. You could start without priming any fuel and the engine would start for a few seconds, and again, and again, and again until the battery is flat. Mixture idle cut-off all the time, no fuel in the engine whatsoever.

1 Like