All of the reviews I’ve seen say that the Honeycomb yoke is head and shoulders above the TB one.

I’m a former maint tech and I’m trying to get the cover off but there is something holding it down at the end near the yoke and I can’t see what. This is strange because I was able to get it apart and add some white lith grease to the shaft a year or so ago, when we were discussing sticking and you posted on this before, but now it won’t come apart. Other than the 9 screws in the bottom what am I missing here?

Other than the two hidden screws under the anti-slip pads, I don’t remember anything unique about taking it apart?

That might be it. In one of your pics I also noticed a slot in the middle of the front edge and was wondering if there might be a latch.

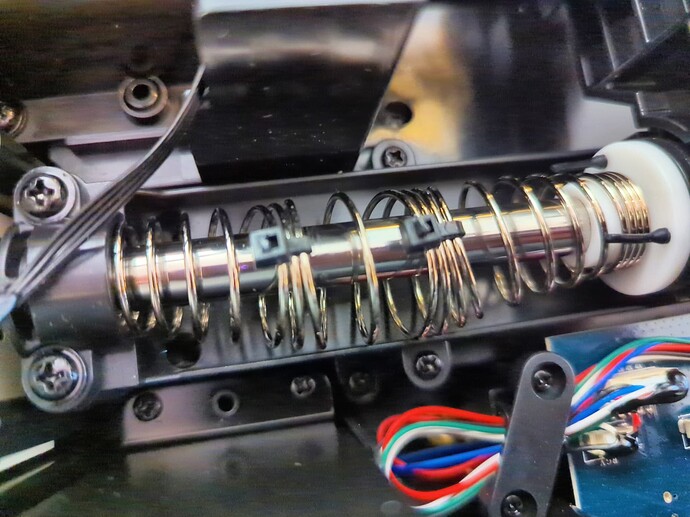

I’m going to try zip ties to compress one small part of the springs. That should ease up the strength of the spring without having to do any major changes.

Thanks for the quick reply!

No worries. Now that I saw this again I must resume my quest for some sort of self-aligning or spherical bearing to replace that plastic one in the cassette on the spring shaft. If the wires didn’t look so delicate I would of pulled the yoke out to peek in there, but didn’t find much if any off-center binding on the yoke itself with the spring shaft removed completely.

Probably something like this

Or a roller version. Just stops the ‘pinch’.

I have a lot of experience with spring rates from R/C and only tinkered with them a little bit, didn’t find much to be gained there. You can really mess up a spring easily(and they are Chineseium) . The progressive rates are about as good as they are going to get. I was trying to tweak the tendency to not have enough strength to return to proper center from back elevator. Which may also be from the spring shaft bearing hanging, this is definitely not at the all-metal price point on the TB. The shifted neutral/dead zone setting covers it without any noticeable issue when flying.

You pointed me to the right place. 25 min after I replied, the job is done.

I was trying to tweak the tendency to not have enough strength to return to proper center from back elevator.

Wow, we have wildly different experiences. My springs were so strong it felt uncomfortable and fine movements forward and back on the yoke were difficult, at best. Most of the time I kept getting jerkiness when trying to gently ease from the centered position to just a hair off center. Hence, why I felt the need to go after the spring tension.

A note to anyone thinking of doing the same thing:

phutyoo is exactly right, it is easy to mess up a spring. This is why I did it the way I did but I’d advise anyone else to zip tie only two coils together at a time. It’s better to tie 3 sets of 2 coils than 2 sets of 3 coils, but I was short on zip ties. If I’d had more, I’d have done 2-2-2 instead of 3-3.

After this, the yoke is silky smooth and light when near the center, delicate movements should be a lot better now.

Here’s a pic:

Mine had that stupid stickiness problem from the beginning (Feb 2023). I didn’t use the yoke much but got back into Flight Simulator a lot more recently, it felt like the stickiness was getting worse in fact. I tried the paper towel thing this week, and was trying to move the yoke through its full range, and finally something inside it snapped, so now it’s actually broken.

I bought it last February, so it’s out of its one-year warranty. Their support said tough luck, need to buy a new one, they don’t even offer paid repair.

I can say that Flight Simulator was actually running for maybe 90 hours since I bought the yoke, probably I used it for maybe 50% of that (I have a joystick which I use for those aircraft), so maybe 50 hours of use?

I’m going to try and take it apart with the help of these pictures, but what a disappointing experience.

I’ve had mine apart several times from the time they came out. Chamfered bushings, polished parts, tweaked springs. It’s the unfixable slop of nylon main bushing for the yoke shaft that hitches off center. My yoke has over 1200 hours on it(I don’t hit AP and leave the room).

Currently he doesn’t have any of these made up right now, but this DOES fix the problem, you can one-hand land a jet with it smoothly. It’s about $40 as a kit shipped, you may have to contact him.

This is just the STL files for DIY printing, but shows what it does, works fantastic:

https://www.etsy.com/listing/1429175008/binding-fixer-v30-for-velocity-one-stl?click_key=91a8f895750be20ae932586a91ae0581818a8369%3A1429175008&click_sum=0f5a2153&ref=shop_home_feat_1

Eventually I’m going to add a proper metal spherical thrust bearing to the cassette that rides along the spring shaft, but haven’t felt like bothering since adding this.

One of these days I hope TB keeps this exact layout but does a ‘pro’ version with updated internals and heavy materials for the yoke and levers. The HC looks like it came from Fanatec, but it didn’t. I’d keep the TB in trade for the better trim wheel, more buttons, and vernier/levers, this tweak helps a lot.

I also had the stickyness and hated it. So with a lot of bad mood I pressed my teeth together and gave a try to this fixer mentioned above. And…

…it works! Yes, it’s up to 40 additional €, but with it, this yoke is just fine. Nothing to complain anymore!

I would strongly suggest a 1 1/4" hose clamp for the inside portion. There’s a huge amount of strain on that plastic cassette that transmits the movement to the “springs”, especially if you push the yoke all the way in and turn it to the left. No amount of lubrication / cleaning the yoke with paper towels would do anything, the problem is with the rod parallel to it: pushing and pulling the yoke creates a torque on the whole plastic piece. That means it isn’t traveling exactly straight, and being pushed at an angle adds even more friction, which increases the torque…

I would suggest anyone who owns it attach a 1 1/4" hose clamp to the split plastic rod at the end. That goes a long way to holding the strain. Sad to think that $2 worth of reinforcement probably would have made the yoke last a lot longer. I think I could have “fixed it” with that alone as a minimum, but I also added metal bracing to each side of the cassette since it was entirely snapped.

Notice the split plastic cylinder at the end of the rod in these pictures:

Look up about 15 posts of that spherical bearing. I want to get one and epoxy it in place of the plastic grommet. The one thing that can’t be modified is the slack in the central yoke shaft. Which the printed support remedies.

I took out one of the foam rings iirc. Also, look at that back elevator dead zone I have some posts back. Returning the elevator lightly doesn’t always center perfectly. That 2-4% helps with precision and sometimes disengaging AP. Forward elevator doesn’t do it

Be careful over tightening it. I did it once and something got broke inside and made horrible noises.

Luckily I had paid an additional insurance for my yoke and I was able to get it replaced without charge or questions.

Just tight the screws evenly and in steps until it feels “better”. To be honest it does improve the stiffness but is not perfect at all, at least not for me.

@GlennyPlays how old is your yoke? What you are describing is what preceded mine breaking. I made the mistake of trying to “break it in” more (since the stickiness was supposed to go away with time according to the FAQ)

There’s a huge amount of strain on that plastic cassette that transmits the movement to the “springs”, especially if you push the yoke all the way in and turn it to the left.

There are more pictures here of how it broke and how I fixed it: My short review of the Turtle Beach VelocityOne Flight Yoke - #7 by darkmark327

You might want to do something similar (hose clamp) before the cassette breaks entirely.

It’s easy to open with a Philips-head screwdriver. If I remember correctly there are 4 screws under the rubber pads but if you’re careful you can just peel the pads back a little and fit the screwdriver in without even messing up the glue.

There is a small hardware mod product out there from someone making them in Europe. I forget what it is called but it is a miracle solution. You will have to do some searching on this forum to find the thread and perhaps on the internet, but it will be time and money well spent. Good searching!

For me it helped a lot, solving that stickiness when you pull/push while pressing down - which you automatically do when using single handed.

Here’s another version of it which helps with both the top and bottom

https://www.etsy.com/uk/listing/1840487911/velocityone-sticking-fix-smoothflight

Note. It’s my son’s shop.

Thanks for that Unfitted!

One last mod attempt before the V1 goes into the recycle bin and I go back to

CH Products Eclipse Yoke.

Sad, Turtle Beach is so close to excellence.

I’ve long given up on it and I’m still using the tm.16000 stick. It has so much better mechanical dampening.

I tried the TB flight stick also and that had poor mechanics as well. ![]() Small range of motion, sloppy dead zone, little to no dampening. The buttons were nice but that was about it.

Small range of motion, sloppy dead zone, little to no dampening. The buttons were nice but that was about it.

Nice looking product. I’d guess it should add dampening forces for a more realistic feel.

Thank you so much for the positive feedback, my son is over the moon