When exactly is carburettor heat used, and how do I detect that there is carburettor icing present? Is it just in cold weather and during a low engine power state like a glide? How do I know when it is absolutely needed? Cheers

These are the notes I took from VATSTAR training

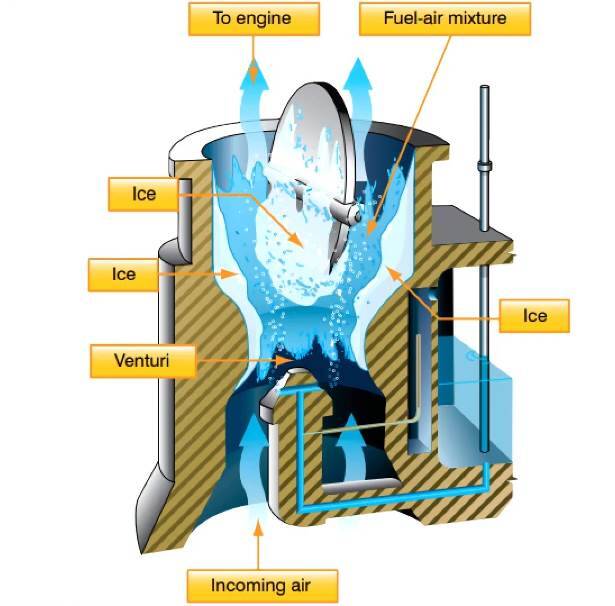

Carburetor Icing

- As the air in a carburetor expands after passing through the venturi, the fuel / air mixture suddenly cools which may cause icing if moisture exists

- Carburetor heat can be applied to counteract the effects of the ice

- When applying heat, you may also notice that your RPM tends to drop, and the engine performance becomes worse due to the high temperature air being less dense, and enriching the “fuel-air” mixture

- Anytime engine roughness occurs, engage heat

- Higher risk when cold outside, moist air / clouds

- When inside green arch on tach, carb heat off, when outside, on

From

Thank you!

Carburettor icing is rare at high RPMs, so the phases of flight that you’d expect to use it are either after startup (check your startup checklist - it will probably be listed) or any time you make a significant reduction in power.

These guys seem to be very shy and don´t dare to speak in class!

The interesting fact is that an airplane engine is literally the same engine like in cars but in more primitive, more lawn-mower or motocross bike style and less ultra-techy.

Thanks for the interesting video.

So airplanes mostly use a cylinder direction what we call “Boxer-engine style” like Porsche cars have, with two spark-plugs to ensure ignition even with thin air and/or problematic cold foggy air. Finally I know what these magnetos are for!

I always wondered what this “magneto” switch in many airplane is and what exactly it does.

The whole series was very informating (there are 9 videos). I believe there are a couple more to come.

As every simplification this holds true for the Lycoming GA engines, which hardly changed in the last 50 years. The GA market is small, people buy the trusted and proven stuff and newly certifying an engine is expensive.

However for already quite some 15 plus years Rotax engines have made initially in LSAs a successful and reliable market entry. These are not boxer style (flat cylinder), offer injection, turbo charging and modern ECUs.

The double ignition is mainly for redundancy and safety (the better fuel burn is a welcome side effect).

I was taught to use carb heat during landings and periods of idle. I never flew in icy cloud conditions so I never had to use it in those conditions.

Carb heat is used at low RPM (for example, below the green arc on the tachometer in the 152). Pull carb heat on when decreasing RPM below the green arc on the tach.) Other than that, carb heat would be used when carb icing is expected and or engine roughness when in high humidity conditions. I’ve had carb ice in the summer time in very humid air. The engine never ran rough but carb icing showed itself when the RPM kept reducing after adding power in cruise flight in a 172. The carb heat was pulled on and the engine RPM increased significantly in a matter of seconds.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.