I had the issue where the roll axis was ‘jittering’ a large degree from centre almost constantly. No amount of calibration would remedy this and I even tried the magnet on the back of the yoke to no avail.

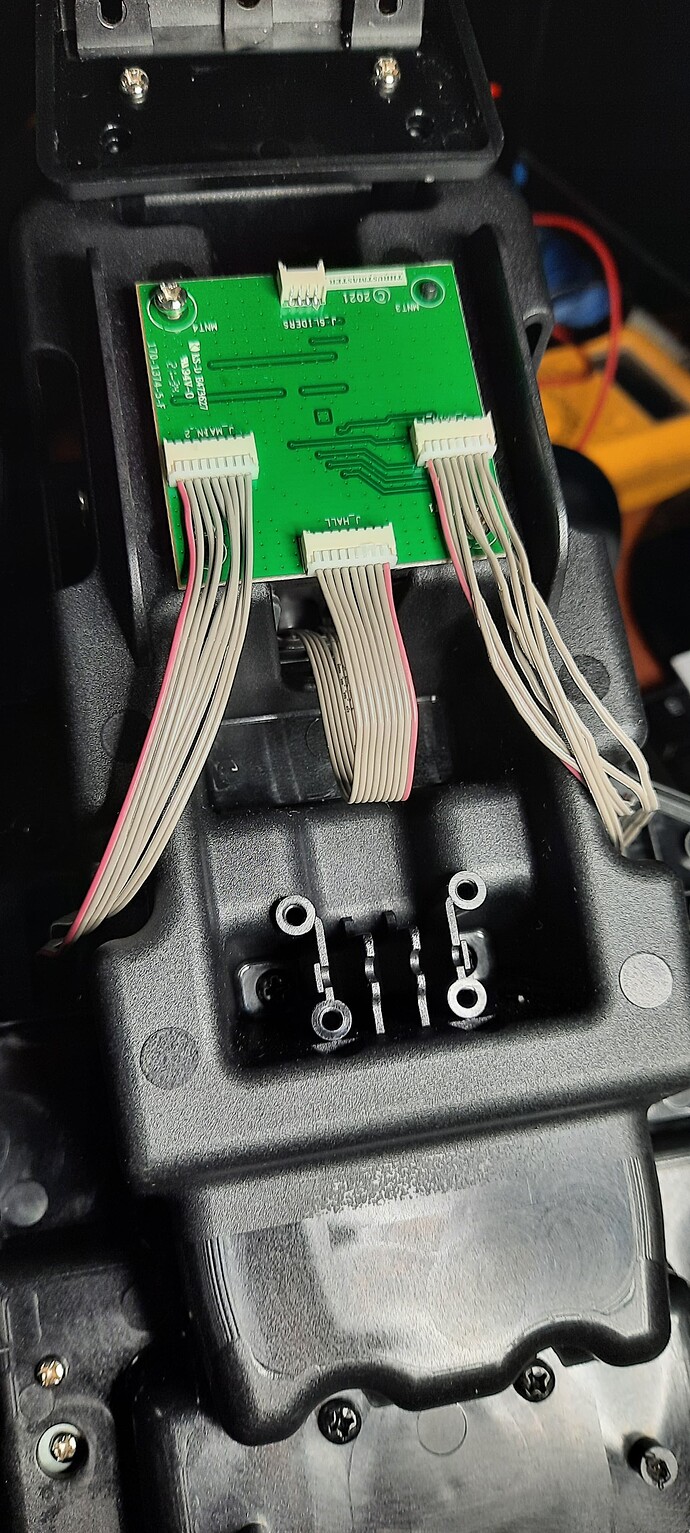

I decided to open it up - I disconnected all the flat ribbon cables and tested each with a multimeter for opens or shorts. All were good. No issues were noted with the circuit boards.

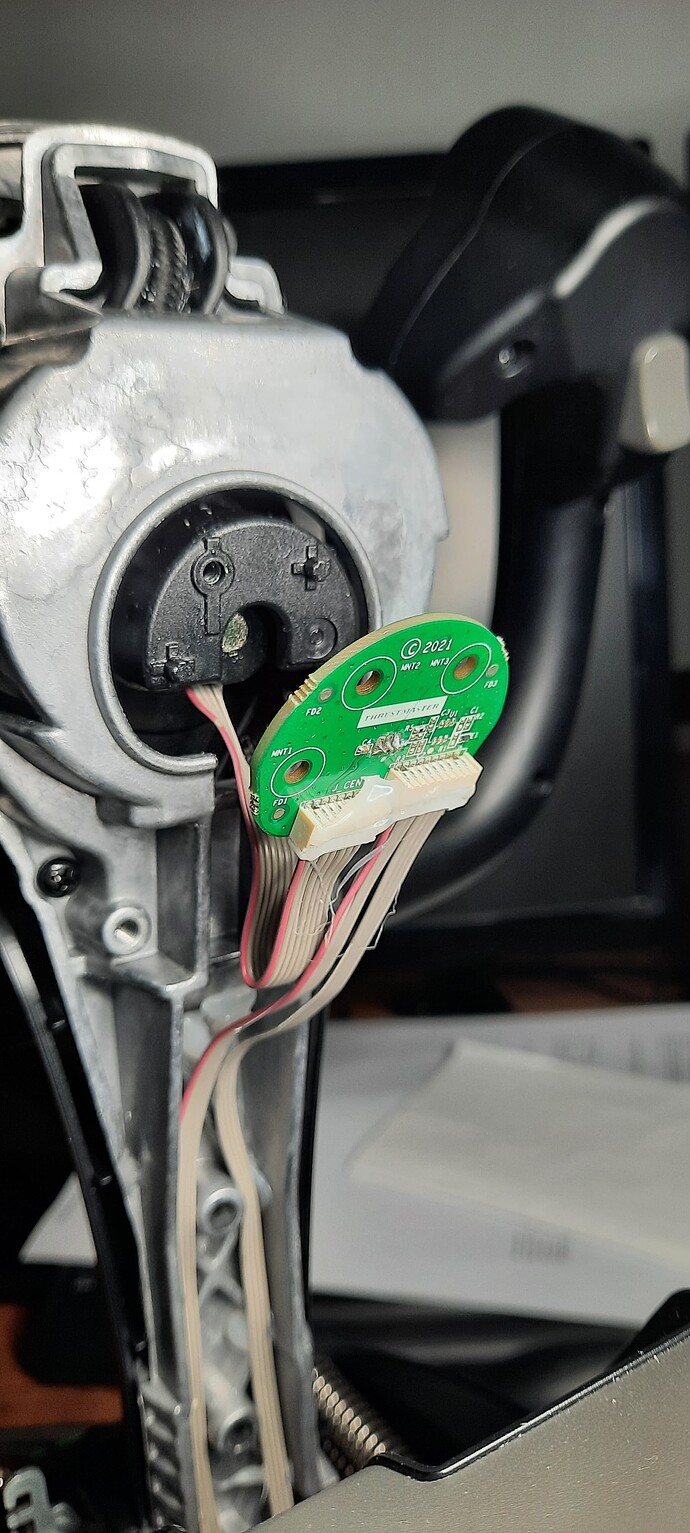

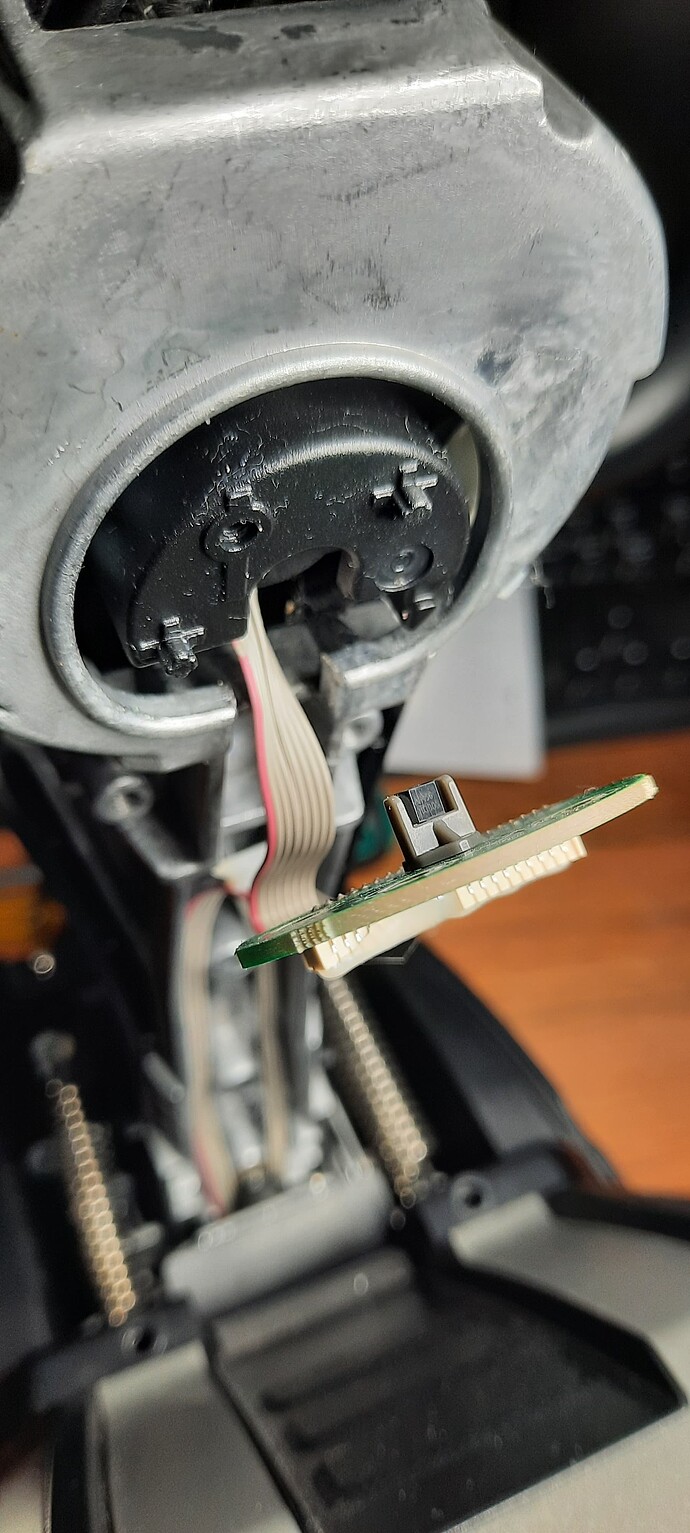

As the roll axis was the issue I removed the back cover of the yoke to access the roll axis hall sensor, found no visible debris but did find the 2 cables connected to the board were under tension due to the way they were glued down to the yoke. I disconnected them, removed the glue and separated the individual wires so they could sit in a relaxed way. I cleaned the hall sensor on the board and the target on the yoke itself, reassembled and the calibration is now rock solid with no erratic responses.

4 Likes