After enjoying my ultra-low-budget 2DOF Motion Simulator for 3 years I decided to build a budget 6DOF Motion Simulator. The jump from a static VR cockpit to a moving motion rig was as much of an immersion leap as from flatscreen to VR, if not more. Upgrading from 2DOF to 6DOF is just as awesome!

UPDATE: Demo video

UPDATE: Full flight video

UPDATE: The detailed 6DOF Motion Simulator Design and Build Plans for my 6DOF Motion Simulator are now available on my website. Having a Full Motion VR Cockpit for under $1000 is not a dream - it’s a (virtual) reality and it feels amazing!

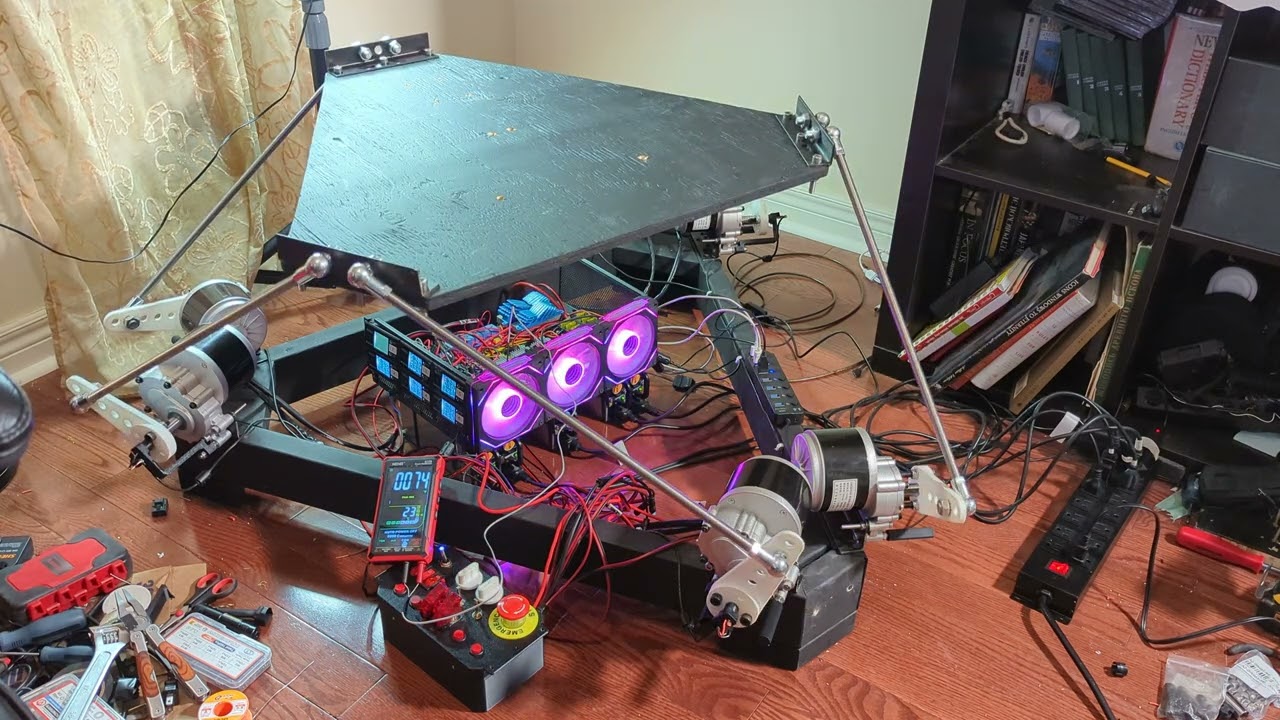

The hexapod geometry with 6 motors allows for 6 degrees of freedom with rotation and translation in any direction.

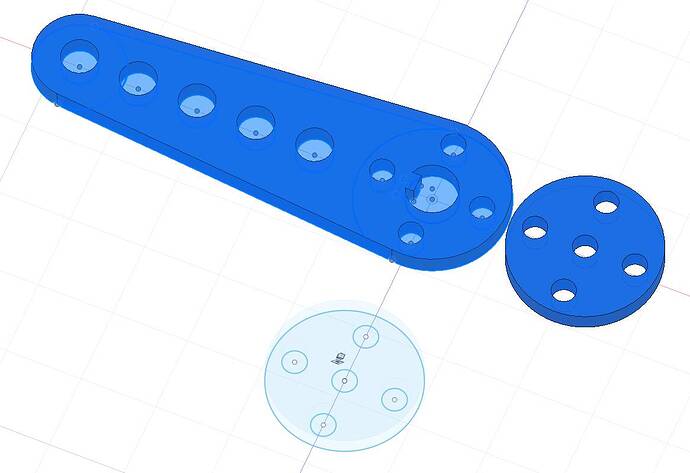

I’ve also reworked the encoder/button/switch boxes. It’s the next level of immersion, at least for me. The build is an ultra-low budget, just like my 2DOF. The cheapest available off-the-shelf 6DOF motion platform costs around $8000 with shipping and some necessary options, and that is too much. I’ve built one for the cost of under $1000 in parts. I’m happy with how the 2DOF wooden frame held on, so I built the 6DOF frame from wood as well. The top platform is cut from a thick plywood I had lying around. The wood has its downsides, obviously, but it also has its upsides: it’s cheap, easy to work with and its natural flex makes the rig less jarring and clunky, which is a problem with many metal motion rigs, while still precise and fast enough.

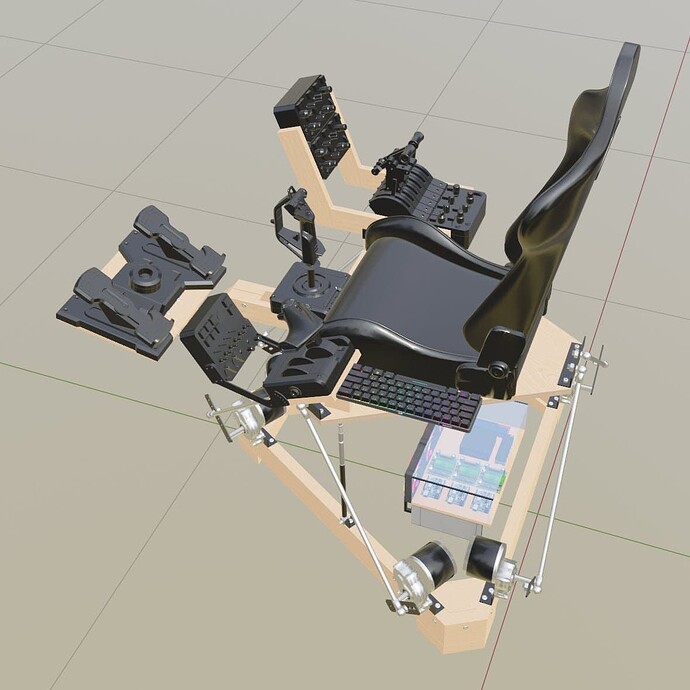

This is the project sketch in the FlightSim yoke configuration. I’ll be using my DIY pendular yoke. The frame will be painted black, but I’m showing a natural wood colour for illustration purposes, so the wooden parts can be easily seen.

FlightSim Joystick/HOTAS Configuration

Racing/trucking configuration.

Note that this is a second priority for me, so it’s not designed to be a low-sitting-position F1 racing rig with a limited range but fast movement. As I’m a Flight Simulation fan, I’m aiming for a smooth and precise motion with a reasonably large range to the limit of what a compact design with inexpensive motors can pull off. Racing can be fun, as is Euro Truck Simulator (and ATS), but those are not as important, so as long as the speed of motion is reasonable, I’ll be OK.

I’m using 6 x 250W Motors, a total of 1500W power supply, 4 Arduino boards, 6 Motor drivers etc.

The Sky is Calling!