Crash Course in Propeller Aerodynamics

Concerning the last Developer Q&A, I’m not entirely sure the developers understand the problem of “missing propeller drag” in the sim. Seb was talking about drag from internal engine components instead of aerodynamic propeller drag. In all fairness, the drag of internal engine components had an effect on propeller windmilling speed and therefore aerodynamic drag produced by the propeller. I’m not a developer to be clear but I doubt this is the real problem. Also it would not explain the lack of drag on turboprops in MSFS as the PT-6 for example is a free turbine engine and therefore not influenced by drag of the engine itself, sure it has some drag from the reduction gearbox and power turbine, but I don’t think this is the real problem.

Edit: after doing some testing it seems like there is propeller drag modelled on certain aircraft. The single engine piston aircraft I have tested seem fairly accurate, the Baron isn’t accurate at all, the landing gear on the Baron does not produce any noticeable drag & able to fly way below Vmca without departure from controlled flight. All three turbo-props have no propeller drag modelled at all. None of the MSFS aircraft have the ability to feather the propellers although on the Kingair and TBM the RPM does drop significantly when selecting feather (but with no change in aerodynamic drag). In short: multi-engine piston aircraft and all three turboprops are significantly flawed.

Definitions

First it is important to understand the following definitions when talking about propellers:

- Blade / Pitch angle - This is the angle between the propeller plane of rotation and the chord line of the blade. On a fixed pitch propeller this angle is fixed, on a Constant Speed Propeller (CSP), this angle is adjusted to balance engine power and propeller power absorbed, controlling the propeller RPM.

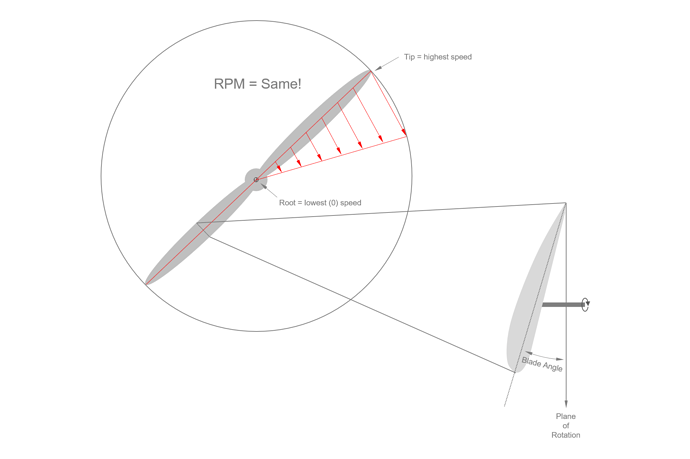

- Washout or twist - The blade angle on a propeller blade is not the same along the whole range of the propeller, as the propeller rotates, the root of the propeller has a lower tangential velocity when compared to the tip of the propeller (compare this with a baseball bat, the tip of the baseball bat has a higher velocity compared to the root). In order to have the same angle of attack on the whole propeller blade the blade angle on the tip is lower than on the root (twist or washout).

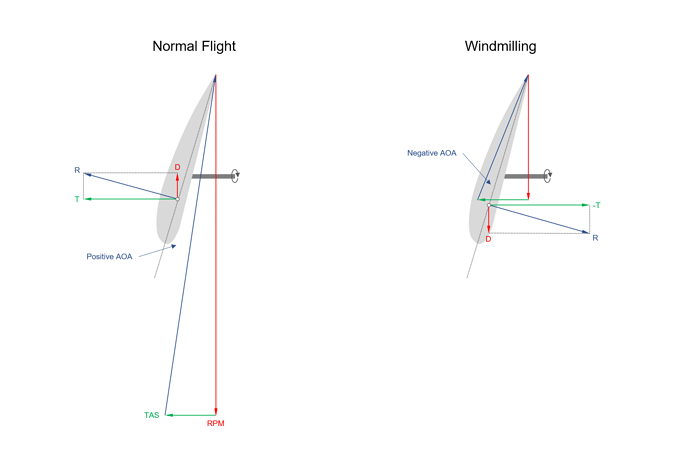

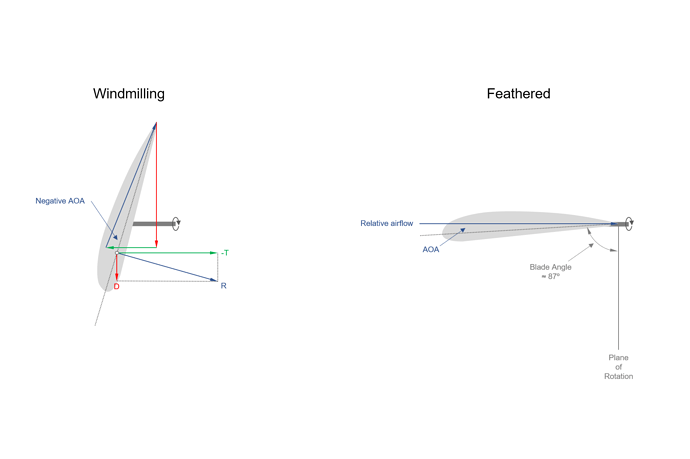

- Windmilling - Is the condition describing the propeller rotating by the forward speed of the aircraft rather than by absorbing power by the engine. When a propeller is said to be windmilling, the propeller is driving the engine instead of the engine driving the propeller. Windmilling is caused by a negative angle of attack on the propeller blade, essentially producing negative thrust (drag). You can look at it as a thrust reverse without having a negative blade angle. The windmilling RPM of a propeller is depending on the drag from the engine (in that regard the devs. are right) and aircraft forward airspeed (TAS). Lower RPM = lower drag, higher RPM = higher drag.

- Forces - There are a lot of forces acting on a propeller, we will be looking at Lift (thrust) and Drag, the rest of the forces are of importance when trying to understand constant speed propellers. Centrifugal Twisting Moment (CTM), Aerodynamic Twisting Moment (ATM), centrifugal (feathering) weights added to the proppeller, springs in the propeller hub etc. we will skip those for now.

- Fine & Coarse Pitch - On a constant speed propeller the blade angle is variable, a small blade angle is called “fine pitch” while a large blade angle is called “coarse” pitch. The finest pitch possible is the low pitch stop in flight and reverse pitch on ground (if installed), the most coarse pitch is the feather position (if installed).

Basics Aerodynamics

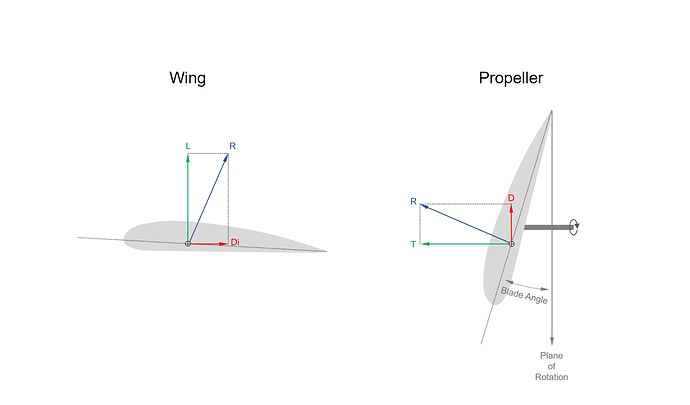

A propeller is an aero foil and essentially behaves like a aircraft wing orientated in the vertical plane. The working principle of a propeller is the same as for a wing, the only difference is that the resultant force is acting mostly vertical on a wing and can be divided into a vertical component (lift) and a horizontal component opposing the direction of movement (Induced Drag), on a propeller this resultant is acting mostly horizontal and can be divided into a horizontal component (Thrust) and a vertical component (Drag).

Very important, this is not the drag we are talking about in regard to the missing aerodynamic drag from (windmilling) propellers!

The engine power has to overcome the drag produced by the propeller, if the two are in balance the propeller RPM is constant, if the engine is producing more power than the propeller is absorbing, the RPM increases, increasing the thrust (and drag) until the two forces are in balance again and vice versa when reducing power.

Regarding constant speed propellers, this becomes a little more complex as there is an extra variable introduced. The propeller blade angle is variable, a constant speed propeller is able to MAINTAIN a certain RPM with an increase or decrease in engine power by modifying the blade angle, therefore changing the power absorbed by the propeller (higher blade angle is more drag and vice versa). For example if engine power is increased, the propeller tends to speed up but the blade angle is then increased producing more thrust (and drag), the increase of power is absorbed by the propeller with no increase in RPM! There is a limit to this, when power is reduced far enough the propeller will eventually reach the minimum blade angle, if power is reduced further the RPM will drop, if power is reduced further then at some point the propeller will start to windmill and drive the engine instead.

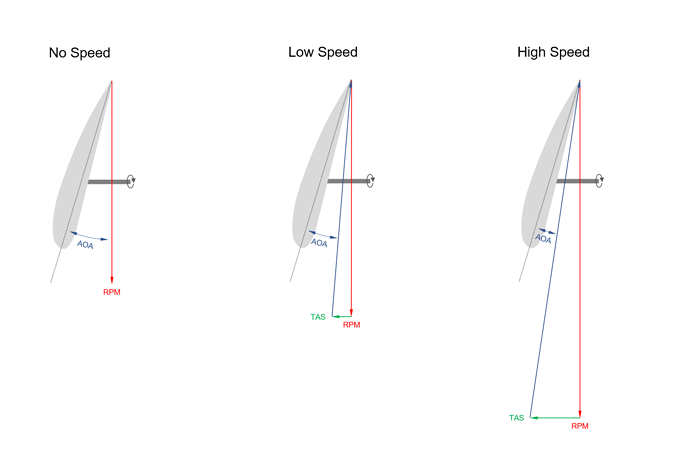

Propeller Angle of Attack

The angle of attack on a propeller is based on two components, the tangential velocity of the propeller and the True Airspeed. The tangential velocity of the propeller is depending on the propeller RPM, higher RPM is higher velocity and vice versa. We can’t call it “RPM” because the RPM is the same for the entire propeller, whereas the tangential velocity is not, it is depending on the location of the propeller, the tip of the propeller having the highest tangential velocity and the root having the lowest (zero velocity). To keep it simple we will call this component RPM, but technically this isn’t correct. I hope the picture below also illustrates clearly how we are looking at the propeller cross section in further examples.

In the first example the aircraft is stationary (TAS = 0), the propeller has a high angle of attack (AOA = blade angle) creating high drag on the engine. If we now release the brakes and start rolling the TAS increases which reduces the angle of attack, the reduced angle of attack causes a reduction in drag. The engine is now producing more power than the propeller is absorbing and therefore the RPM increases. This increases the angle of attack again to bring it back in balance, this is the constant force balance in play during flight. It is also the reason why on a fixed pitch propeller (e.g. Cessna 172) the RPM increases with increasing airspeed for a given engine power setting and vice versa.

Windmilling

Now the core of the issue. What happens if the we reduce power all the way to idle in flight? If the engine is not producing any power why doesn’t the propeller (and therefore engine) stop rotating? As soon as the engine fails or power is reduced to idle, the RPM drops significantly as the propeller absorbs more power than the engine is producing, eventually the angle of attack on the propeller becomes negative and the forces acting on the propeller will basically flip. Positive thrust becomes negative thrust (THE DRAG WE ARE MISSING IN MSFS) and drag becomes the driving force, keeping the propeller and engine rotating. This drag is very significant in real life and cuts the glide ratio short by a significant amount, the deceleration in real life is therefore also significantly higher than in MSFS and it is possible to make steeper approaches without picking up speed.

Note that a windmilling propeller basically acts like a thrust reverser, but at a positive blade angle.

Single Engine versus Multi-engine

Without diving deep into the working principle of a Constant Speed Propeller, Propeller Governors etc. There is a noticeable difference between single engine and multi-engine aircraft. The principles are all the same independent if we are talking about single-engine, multi-engine, fixed pitch or constant speed propellers. Also on a constant speed propeller the engine will windmill, the reason is simple, a constant speed propeller (it is in the name) wants to maintain a constant propeller RPM. If an engine fails or power is reduced to idle the constant speed propeller will drive the propeller to the fine pitch stop and from there it will essentially behave like a fixed pitch propeller.

Belief it or not, windmilling on a single engine aircraft is actually beneficial. From an aerodynamic and glide range standpoint, windmilling obviously isn’t a great benefit. But only having one engine, the main priority should be to restart the engine, windmilling of the propeller keeps the engine turning and increases the possibility of restarting the engine in flight. This is the principle difference between single and multi-engine aircraft. On a multi-engine aircraft an engine failure will not only cause asymmetric thrust, on top of this the windmilling propeller will cause a load of drag. On a multi-engine aircraft the priority is therefore to reduce the drag, secure the engine and continue flight on the remaining engine.

Reducing the drag of the propeller and stopping the engine is done by “feathering” the propeller. The blade angle is increased to a near 90 degrees which results in zero resulting force on the propeller blade, the propeller stops rotating and drag from a windmilling propeller is canceled. Feathering can be accomplished manually or automatically by the aircraft (i.e. auto-feather). Nice detail, the propeller blade angle when feathered is not exactly 90 degrees (few degrees lower in fact), if the propeller blade angle would be increased to 90 degrees the propeller blade would start to act like a wing and will produce a slight lift force (and therefore drag), the angle of attack is therefore kept slightly negative.

This is exactly the next problem in MSFS, last time I checked propellers are not able to feather, neither does the propeller produce drag as we know so the propeller performance in MSFS is basically a feathered prop anyway. When propeller drag becomes implemented feathering would become very important. At this moment, accurate simulation of asymmetric thrust and drag on multi-engine aircraft is unavailable.

In all cases below, flight model set to MODERN, assistance set to HARD, community folder completely emptied, ISA conditions, no wind.

TBM 930

Maximum weight, 120 kts glide speed, flown with FLC on autopilot, prop first feathered and then windmilling. I cut the engine (by closing fuel selector) overhead an airport at 3000 ft, ISA, no wind, glided down to 0 feet, paused the sim, took the drone camera to check my location, looked it up on Bing maps and measured the distance.

Prop. Feathered:

Propeller speed = 260 RPM

Glide range: 17.5 km = 57400 ft

Glide ratio = 57400 / 3000 = 1:19,13

Prop. windmilling:

Propeller speed = 960 RPM

Glide range: 17.1 km = 56088 ft

Glide ratio = 56088 / 3000 = 1:18,70

My methods are a little bit mickey mouse and completely accurate, the autopilot started to level off slightly when doing the glide ratio test with feathered propeller because I put 0 ft in the altitude preselect so thats were the extra 400 m likely comes from. It is safe to assume that there is absolutely no drag modeled on the TBM…

Next test, FLC at 120kt in descend, measuring vertical speed:

Flight idle: -700 ft/min

Windmilling: -650 ft/min

Feathered: -700 ft/min

Full reverse: -900 ft/min

Conclusion, no windmilling drag at all. In all situations the vertical rate is fluctuating between 650 and 700 ft/min.

Beechcraft G36 Bonanza

Speed 110 kts at FLC, max. weight:

Power idle: -1100 ft/min

Engine off: -1300 ft/min (mixture cut-off)

Low RPM: -1100 ft/min (mixture cut-off and prop full back)

Below, same test as TBM, power cut at 3000 ft overhead an aerodrome. Mixture cut-off, prop in low RPM, 110 kts at full weight according to the POH it should result in a glide ratio of 1.7 nm per 1000 ft.

Glide range: 4.9 nm

Glide ratio: 4.9 / 3 = 1,64 nm per 1000 ft

Conclusion, the G36 is pretty accurate! Maybe the problem only concerns turboprops?

Beechcraft Baron

Speed 110 kts at FLC, max. weight:

Power idle: -1000 ft/min

Engines off: -1450 ft/min (mixtures cut-off)

Props feathered: -1450 ft/min

Conclusion, not sure if the increase in rate if descent is because of losing idle thrust or if it is because of propeller drag. The props don’t feather, absolutely no response to propeller lever (RPM stays the same when feathering). Interestingly I accidentally left the gear down during this test so I rerun the test with gear-up with same results! The landing gear on the Baron does not seem to create a noticeable increase in drag.

Beechcraft Baron - Vmca demonstration

Beechcraft Baron

One engine full power, the critical engine windmilling

Take-off flaps, gear-up

ISA conditions

Max. TOW, aft CG

Seems the aircraft stalls before losing control due to asymmetric thrust and drag. I haven’t flown the Baron myself but I have heard stories about how it is handling single engine go-arounds and I even know someone who died practising single-engine go-around on a Baron. Can anybody with experience on the Baron confirm whether this behaviour is correct? Is it still climbing this well on one engine with flaps at take-off at speeds way below Vyse?

By the way the rudder axis on my joystick is seriously borked so I’m lacking precise control over the rudder…

I noticed I shutdown the wrong engine, I had the right engine in my head as being critical, forgot that the aircraft I used to fly has counter rotating props, oops…

Second attempt: now with the critical engine failed, 50% payload, gear down for some extra drag, first one flaps take-off, second one flaps landing:

Beechcraft Kingair

The Beechcraft Kingair is an absolute joke. I have flown this aircraft in real life, I can see it is seriously flawed.

Max. take-off weight, speed 140 kts on autopilot using FLC:

Power idle: -300 ft/min

Full reverse: -1150 ft/min

Engines shutdown, props full forward: -850 ft/min

Props feathered: -850 ft/min

I didn’t note the RPMs, the RPM does drop significantly when selecting feather, but with no effect on the aircraft drag. The difference between flight idle and engines shutdown is likely not an increase in drag but rather a way too high flight idle power setting…

When shutting down the critical engine (windmilling) and adding full power on the life engine, the aircraft stalls way before running out of rudder to counter the asymmetric thrust and drag. Second try with flaps in landing position to lower the stall speed, able to fly just 77 kts with the joke full back, rudder full in just keeping the slip indicator centered, again no departure from controlled flight below Vmca.

Cessna Caravan

Max. take-off weight, 110 kts on FLC (no idea what best glide speed is, I just picked a speed).

Power idle: -650 ft/min

Full reverse: -1050 ft/min

Engine shutdown, prop full forward: -900 ft/min

Prop feathered: -900 ft/min

On the Cessna Caravan the prop RPM does not respond when selecting feather. RPM remains the same. Conclusion, the three turbo props seem to suffer the most from incorrect (completely missing) propeller drag.