If you can wait a bit i can help you out with the code. I will post my code on github and make it flexibel for use so you can use it only with your pedals or complete with roll, pitch and yaw (pedals).

I would love to try out your code. I plan on making a full DIY pedals and yoke. Just because. Then I’ll probably sell the Saitek units.

I noted that the r_eng and l_eng inputs on the motor controller are connected to pin 11 on the Arduino board. Why not connect them to an Arduino 5v output? High and low braking work the same, right?

I’m going to try using current control instead of end-stop switches. One for each direction.

I’m certainly not a fan of the way this motor whines. It is annoyingly loud. Wonder if there’s a way to quiet it down. Maybe a couple of capacitors or something. I need to research that.

Hi, yes, you can connect them to 5v but then the driver board will allways enabled. Only my sense of security says to me „it would be better to have more control“.

I‘m working on a small redesign of your mod and i will start printing the parts next week. After that i will start with the coding and posting it on Github. The base code will be the Fino Repository.

Where would I connect the 5v? To each side of the motor?

Yes, you have to connect both r_en and l_en to 5v otherwise the motordriver will not work.

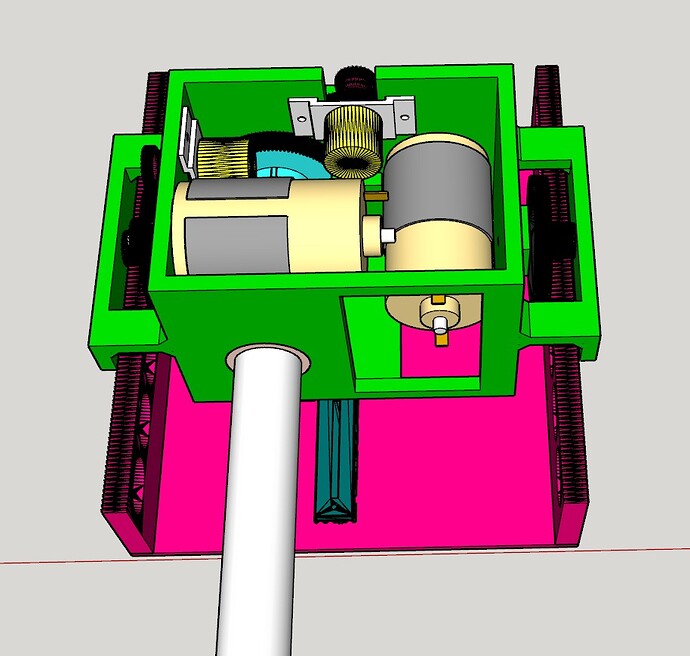

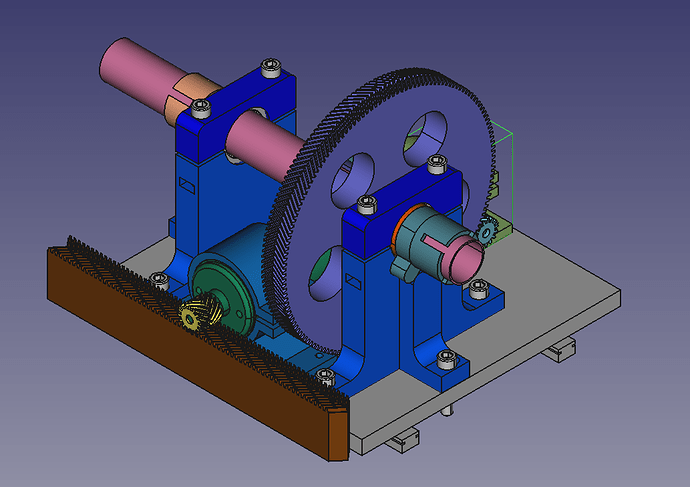

Hi, this is my first plot of my FFB Yoke, inspired by your mod. It’s not tested yet!

The roll can handle nearly 180 degree (i hope).

I’ve implemented two Potis for Pitch because i don’t know which one i want to use yet. The Gearbox is now printing on my Prusa and all parts will need 2-3 days for printing.

In the meantime i will design the housing for the electronic and begin so setup a github repo for the coding part.

I will release oll my work on Github and Thingiverse when it’s finished and working.

I like it.

Took me a second to see how you had the Roll set up.

It looks like you have both the linear and 10-turn potentiometers installed for the pitch. You only need one of them. I opted for the linear after finding that the 10-turn caused too much drag.

The printing is ongoing and the Repository is created.

I’m curious about how sturdy the outrigger support that holds pitch compound gear will be. The roll gear has 3 points of contact with the housing, yet the pitch only has 2. I wonder i f this would allow for some flex. Adding a 3rd pint of contact might not be a bad idea.

I‘ve done some design changes after first prints of the gearhouse. I‘ve made a big error on my first design because there is no way to insert the roll gear ![]()

I‘ve also done some changes on the gear for the yoke pipe and i guess there will be some more changes in future.

The printing time for the geahouse was 17 hours and some hours for the gears so i will need some days to print out all the party. I will post some pictures when the print is finished and put these things together.

I was thinkiong about your post. Yes, it could be happened that the Roll Gears will move away from each other when the Yoke is rolling to the right. I will test it when the prints are finished. If it’s happened then it coul be a solution to add a second roll gear on the right side, but only the left side is motorized.

Like this:

My first tests are promissing but my Resin seems not to be the best material for gears. They are looking really good but breaking really fast. I’m thinking about a new design because i saw an another FFB Yoke project on thingiverse and want to test it out.

That’s the one I’m coming from. I have built this yoke and am now building JCS’ as I hope to have smoother movements. The one from Jay works good but the axial movement is somewhat “stuttering”.

I’m sorry to hear that. I do remember a video that talks about gear material. The gist was resin is brittle, nylon is best, PLA works well. I’m using PLA with no issues.

You could have the gears printed. Where are you located?

Hi,

I’m located in germany. I have also a Prusa I3 Mk3 printer here and now i’m printing in PLA.

Do you mean Pitch with “axial movement stuttering”?

May be a combination of both would be working, Pitch from JCS and Roll from the another FFB Yoke Project?

I’m in Germany as well. Yes, pitch does not run smoothly at all, but - and this is my main concern - that’s mainly because of the tension on the roll axis! I think JCS’ solution is much better!

I’ve had zero issues with PLA and/or PETG for gears so far. Maybe your settings are off?

Good to hear you have filament printer. I printed mine with a .2mm nozzle. A .4mm nozzle did not retain the definition of the gear’s teeth. I also dried my filament for a day before printing the gears.

I use calcium sulfanate as my lubrication.

I’ve some new ideas to enhance and make the construction poorer and easier to print. I’m really busy this week so i guess i will pos a new status next weeks.

cheers.