Confirm this is not fixed with SU4. Very disappointing! Best part of the bravo

I agree with you. It might be just my imagination (or wishful thinking) but it seemed “slightly” better after the newest update…but just slightly. It’s still way off of how it was before the last world update which was pretty darned close to how it is supposed to act in a real Cessna. I filed another bug report with Zendesk and I would encourage everyone with this problem to do the same so it will get noticed and hopefully corrected soon.

Can anyone with real-world piloting experience answer a quick question – about how many degrees of rotation of the trim wheel does it take to go from level to a standard climb in a typical GA plane (for instance, a Cessna 172)?

Is it closer to 5 degrees, or closer to 90? Or significantly larger or smaller than those?

Probably not related to your issue (using the digital trim wheel on the Bravo), but did you happen to be in VR when you tried this test?

I had come up with a way, using freeware apps, to get back most of the lost speed while still maintaining precision trim movements with the wheel when you wanted. Unfortunately, I just discovered that this method barely helps with the speed in VR because the game limits the button repeat rate to about half(?) of what it is in 2D. That means that whether we are repeating the button presses rapidly with a digital trim wheel (which probably doesn’t repeat them fast enough to matter) or boosting the repeat rate with fsuipc or some other app, we are seemingly limited to half the movement speed in VR. I will need to re-think my solution since I fly almost exclusively in VR.

See this report (with video demonstrating the problem) that I just added to the bugs forum:

Why am I surprised that the issue is still thier. Works without issue in Xplane 11. Why is is so hard for the devs to get ■■■■ fixed?

The devs could easily implement a “increase trim x10” and “decrease trim x10” keybinding which works exactly like the current one - but with 10-times the increase/decrease and all we had to do is binding our Bravo trim wheel to the new x10 bindings. Topic solved.

To be honest I was wondering myself if trimming is really that stupid and if I completely misunderstood every single time I saw some real pilots trimming their real aircrafts. Turns out it’s a bug, not a feature.

That seems like a good idea. The disadvantage is that anything you map to this binding would always move at 10x. So, when you wanted only a small movement, you would have to use another button (which makes you wonder why you don’t just use a button for all your trimming instead of a wheel). I like using a wheel, so I would like speed AND precision. That’s what I’m trying to come up with.

@VisitingNutria4 , @JTzee2929 , @BassMarmot48037 and all the others hoping for a fix for this issue, do you want the good news or the bad news?

The good news is that I came up with a way that works for my Desktop Aviator digital trim wheel and I think it will also work for the Bravo, Logitech, and other digital trim wheels! It not only give you a speed boost for when you are trying move the trim quickly, but also allows you to make slow single-step movements when you are trying to get those last few tweaks done for perfect trim!

The bad news is that I couldn’t just link you to a file or solution. I could only fix this for my particular trim wheel and then try to teach others how to fix it for the other brands with a Video Tutorial. Hopefully it will work and we’ll soon have examples for all. So, if you want to be the first to fix it for Bravo or whatever, get out your school clothes, sharpen your pencils, and go through the Tutorial!

Really, really hope this helps and maybe gives a better solution than either of the Asobo approaches so far.

It’s the fastest way to implement a temporary fix.

Ideally MSFS would treat the trim wheel somewhat like the alt bug: If you keep moving the steps you’re doing are getting larger.

Perfect (and only correct) solution would be to do something like “mouse acceleration”. If you turn slowly you’re doing baby steps but if you’re going fast the steps are accelerated and you do really large steps.

It’s weird that they implement changes “only professional pilots” will notice but don’t bugfix something nearly everybody notices.

Shouldn’t the amount of trim adjustment depend exactly and only on how far the wheel was turned? Acceleration of any kind sounds very wrong and would make it difficult to trim in one direction, then trim back because moving the wheel the same amount might not give the same result.

Ideally the amount you move your wheel in real life would move the wheel in the sim exactly the same number of degrees. But, your wheel and the sim don’t communicate on how each plane is different in its animation of the trim wheel. And, we each have different size trim wheels so what is " the same amount of movement "?

Acceleration is exactly what happens when you hold down a controller button or keyboard to move the trim. When you first hit it it just moves it one step, but as it sees that you are holding it down it accelerates it into about 30 presses per second. The fact that it has a delay before accelerating is necessary but also means that it is really really hard to move it one direction a certain amount and then move it back exactly the same amount.

Given that we likely need to do more than one step for each button press generated by a digital trim wheel if we don’t want to have to move our physical trim wheel literally hundreds of times to adjust trim from one extreme to another, we kind of do need a way to speed it up when we want speed. That’s why having speed when you’re trying to move big distances is good but still being able to do single step movements when you’re trying to get the final perfect trim set is important too.

On the other hand, an analog trim wheel mapped to an axis is the closest to the ideal that you mentioned. It may not match exactly the animated movement in the sim, but it will move the same amount every time no matter how fast you move the wheel or which direction you are going. That’s why in my tutorial video I say that an analog trim wheel is really the best solution…EXCEPT for the big caveat related to autopilot as a show in my video. If we all had motorized trim wheels that adjust themselves in real life as the autopilot adjusts the trim, then we wouldn’t be having any of these discussions.

The acceleration as a change in the speed of repeat button presses is how keyboard repeat works, for instance, when you press a key and hold it down. However, a trim wheel isn’t a button that you hold down – it sends multiple trigger events as you continue to move it. Just like when using the thumb knobs on the Honeycomb Bravo to input an altitude or speed target, acceleration is not something I’d want – I frequently find the acceleration messes up my input, causing me to massively overshoot and require a lot more time to dial in the right target.

So the sim should be able to apply a consistent delta for each trigger event, representing a certain rotational movement of the wheel. Each plane could have a configuration option in its config file saying how many degrees of trim wheel equals how many degrees of change to the pitch trim, etc.

This of course is not how it works, which is a problem.

As for the size of the wheel – all wheels have 360 degrees. ![]() However they may trigger the event at different increments, and this would be something you’d need to configure in the controller settings (likely with a preset for common devices).

However they may trigger the event at different increments, and this would be something you’d need to configure in the controller settings (likely with a preset for common devices).

Acceleration is very very bad because it means you can’t reverse an action – if you overshoot by 1.5 seconds worth of button-press, or by 20 degrees of rotation, then a reverse action of 1.5 seconds or 20 degrees in the other direction may produce a much smaller delta, failing to undo your overshooting.

Worse, if you keep holding the button or rotating the wheel, you’ll accelerate again, suddenly overshooting your target in the other direction. Now you have to go back a third time. Big no-no in my book. ![]()

This is unnecessary; the wheel on the Bravo for instance is not motorized, and it has no interference with the autopilot. All that’s needed is for a specific rotation of the physical wheel to apply the same specific rotation to the virtual wheel, whatever its current virtual position is.

That’s it. No analog wheel, no motors needed.

@Vibstronium All well thought out and clear.

You are correct about how it could/should work. However, I believe there are some fundamental hardware/software limitations that make it impossible to have it work exactly like that.

Digital trim wheels do, as you say, put out multiple trigger events (button presses) as you continue to move it. If the rate of these trigger events was directly related to rotation speed, such that it acted as an accurate positional encoder, then all would be good. But the rate is not directly related to rotation speed, because of the hardware/software limitation I mentioned. The sim can only see button presses up to a certain rate. This limit seems to be about 30 times per second in 2D and 15 times per second in VR. The fact that 2D and VR varies is a huge problem for having consistent behavior of the trim wheel, but let’s ignore that for a moment and just focus on 2D.

Either the wheel electronics itself (as in the case of my Desktop Aviator trim wheel) must limit the trigger event rate to less than the limit (mine, unfortunately, limits it to 6 times per second maximum and I may do a DIY thing to at least double that) or the sim itself will “limit” in the sense that it will start missing events. Thus, once you are rotating your physical wheel faster than a certain (not very fast) rate, the speed of the wheel in the sim stops increasing even as you move the physical wheel faster and faster. This “deceleration” is there whether you want it or not. This automatically means that your fears of having different behavior with different directions or different speeds is already present. Some form of acceleration is only an attempt to overcome some of this to allow the in-sim wheel to move at more than a crawl.

Your point about overshooting one way and then overshooting the other is exactly why my work-around only accelerates if you move the wheel quickly. If you are narrowing in on your ideal trim, you move the wheel slowly (as is intuitive) and you get single, un-accelerated, events and can precisely adjust up and down until it’s just as you want.

An analog wheel will always move the wheel in the game the same amount for a give rotation of the physical wheel because it doesn’t matter if events are missed. The axis will always end up at the same place and the sim will end up there too. But, that introduces the autopilot problem and thus the “need” for a way to physically move the physical wheel when the AP is actively adjusting trim. Since I don’t want to invest in a motorized trim wheel, my other thought is an analog wheel without physical stops (but, of course, it has to stop incrementing/decrementing the axis when it gets to the “ends”) that can have it’s location value written by the sim. Thus the autopilot can “move” the trim wheel logically, if not physically. This would be the best of both worlds and, in fact, I’d like to try to do this somehow someday.

Good analysis, you have thought about this issue in detail.

I do think they could make improvements on how the sim responds to fast button press events – there should not be anything preventing it from accepting multiple press events on a single frame and processing all of them.

But if they choose not to do this, your recommendations are a good workaround yes.

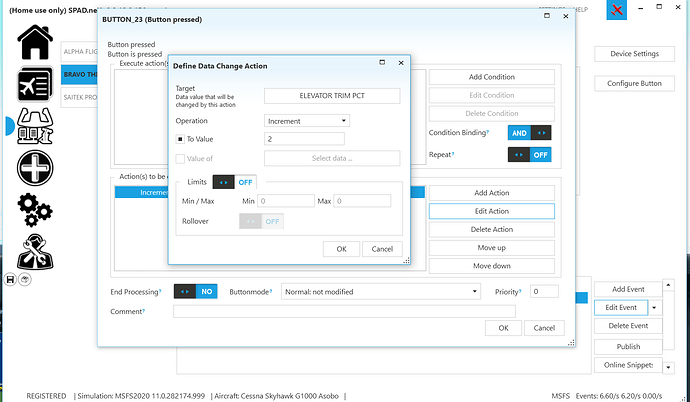

I’ve done some testing in spad.next (which I got a while ago to work around multiple input problems and LOVE IT). If I switch from using the ‘trim up’ / ‘trim down’ events to directly incrementing/decrementing the percentage of trim by 2% on every button press, I get results that subjectively “feel good” to me in a C172 but I have literally no idea whether it is correct or off by an order of magnitude from real life.

I’ve ended up with this setting, incrementing the pitch trim in radians directly, not sure if it make a huge difference.  Tested in the Carenado PA28 and ran it past a friend for advice on speed. Might or might not be semi-realistic, but it feels good.

Tested in the Carenado PA28 and ran it past a friend for advice on speed. Might or might not be semi-realistic, but it feels good.

You don’t do that with a trim wheel. That’s what the elevator is for.

You first set the correct attitude using the elevator then when your speed stabilizes use the trim wheel to zero out the forces, so you don’t have to pull or push for it to stay at the position you want it in.

Using an analogy with sim yokes trimming would be more like adjusting the springs, so that the center the yoke wants to return to moves back and forth.

In general turning the trim wheel 90 degrees is a pretty big change. Rarely do you need more.

I’m not sure what you mean by “that”. Trimming is for setting the trim, yes.

Ah, I went back several messages and I think I see what you’re replying to.  (And thanks for the tip reminder about using the elevator first, then trimming – IRL I believe you’d also get the benefit of feeling the force on the yoke/stick from the elevators, which would help you dial in the final trim.)

(And thanks for the tip reminder about using the elevator first, then trimming – IRL I believe you’d also get the benefit of feeling the force on the yoke/stick from the elevators, which would help you dial in the final trim.)

The point is – when making a normal adjustment like changing a climb or descent angle, how much trim adjustment does one make in terms of degrees of wheel rotation or inches of wheel edge movement?

If 90 degrees of motion would rarely be used, how many degrees would be used in making this sort of adjustment? 5 degrees? 10? 15?

If it’s not expected to be 90 degrees but 10, and 10 is what is actually required, then it’s good.

If it’s expected to be 10, and 90 is what’s actually required, then that’s bad.

You can see the trim wheel in the 3d cockpit. It should move by the same angle as on the controller. Right now it’s like 1/10 or less.

Since the physical yoke doesn’t match the virtual yoke, I wouldn’t expect the physical wheel to match the virtual wheel on screen either. I’m much more interested in the effect on the virtual plane.

I haven’t looked at the AIRCRAFT.CFG file for FS2020 yet (there must be one), but as I have done with FSX, one can go into the file and edit certain settings, such as how far the trim moves (trim effectiveness) for each click. Is it maybe possible to do this in FS2020?

Of course, it would be better if Asobo fixed it.

Seems this bug report made it into the Feedback Snapshot:

This one is more recent and more specific to the Trim Wheel, so hopefully it stays open, but I’m also going to put my votes over there too.