There appears to be a bug in the core mixture logic for turbocharged piston engines in MSFS. In real-life, a turbocharged fuel-injected engine should be able to climb with full-rich fuel mixture all the way to the critical altitude for the turbocharger with no loss of power or engine performance. The turbocharger can compensate for lower air pressure with altitude by compressing more air into the intake manifold and allowing the engine to operate with the same manifold pressure as it would at sea level. This is reflected in the POH instructions for multiple real-world turbocharged aircraft, which generally recommend maintaining a steady manifold pressure during the climb and keeping the mixture at full-rich until reaching the cruising altitude.

However, in Microsoft Flight Simulator, turbocharged engines gradually lose power with altitude when the mixture is set to full-rich. This can be observed by modifying the engines.cfg file for the stock G36 Bonanza to specify a turbocharged engine (turbocharged = 1 instead of 0) and then setting a realistic critical altitude for the turbocharger (for a real-world Bonanza outfitted with an aftermarket turbo, this appears to be about 18,000 ft). If the mixture is set to full-rich in MSFS, the engine will gradually lose power with altitude, eventually resulting in a complete inability to continue climbing. Leaning the mixture under these circumstances increases the fuel flow dramatically, and the engine develops a more realistic amount of power.

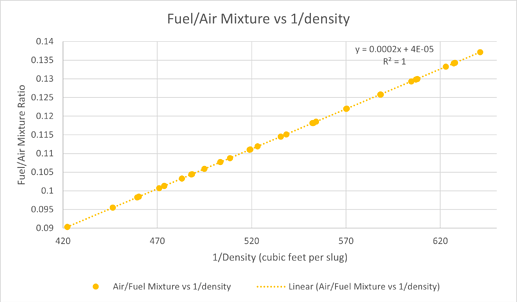

The behavior appears similar to the mixture bug that was fixed last fall for naturally-aspirated piston airplanes. In that case, maximum fuel flow would occur at a mixture setting of 91% at sea-level. Full-rich mixture produced a lower fuel flow than 91% mixture. That behavior was fixed at sea-level, but it continues to occur at higher altitudes for both naturally-aspirated and turbocharged engines. For turbocharged engines, it should not occur, at least until the critical altitude for the turbocharger.